41

GRUPPO DI

CARICAMENTO

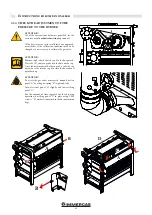

Instructions for the installer

3.22 SYSTEM FILLING AND EMPTYING

Attention!

Do not mix the heating water with antifreeze or anti-

corrosion substances at incorrect concentrations!

This may damage the gaskets and cause noise to

develop during operation.

Immergas will not be held liable in case of damage

caused to people, animals or property due to failure

to observe the above.

Once all of the connections for the system have been set up, it is possible

to fill the circuit.

To fill the system it is possible to set up a loading valve on the system's

return pipe.

It can also be filled through the drain valve installed on the boiler

return manifold.

The boiler is equipped with an emptying valve, positioned as indicated

in the figure of parag. 2.2. This valve must

never

be used to empty the

system, since all of the dirt contained in the system may accumulate

in the boiler, jeopardising smooth operation. Accordingly, the system

must be equipped with its own emptying valve, of a suitable size for

the flow rate of the system.

3.23 BOILER FROST PROTECTION

If the flow temperature (measured at the global flow NTC) should fall

below 7°C the system pump starts operating.

If the temperature drops any further (under 3°C), all modules are

commissioned at the minimum power until the return temperature does

not reach 10°C. This device protects the boiler only. In order to protect

the system as well, it is necessary to add antifreeze liquid.

NB: The antifreeze liquid must be compatible with materials present

in the entire system and tolerable for aluminium alloys.

EXAMPLE OF SYSTEM LOADING UNIT

LOADING

UNIT