18

1

2

3

4

5

6

6

INTERNO

CENTRALE

TERMICA

ESTERNO

CENTRALE

TERMICA

Instructions for the installer

3.6 GAS CONNECTION

The gas intake pipe must be connected to the boiler using the respective

G 3" fitting as indicated in parag. 2.3.

The supply pipe must have a section equal to or

larger than the one used

in the boiler and must nevertheless provide the correct gas pressure.

It is nevertheless advisable to adhere to the standard specifications

and requirements in force, setting up a cut-off valve, gas filter, anti-

vibration joint, etc.

B

efore commissioning an internal gas distribution system and therefore,

before connecting it to the meter, it is necessary to thoroughly check

the seal.

If any part of the system is not in view, the sealing test must be carried

out before covering the pipe.

Danger!

The gas connection must be set up by an authorised

installation technician who must observe and apply

the contents of the legislation in force and the local

requirements of the gas supply company, as incorrect

installation can cause damage to people, animals

and property, for which the manufacturer will not

be held liable.

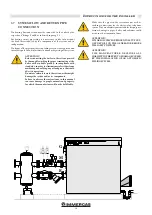

Key:

1 - Fuel shut-off valve

2 - Double membrane regulator

3 - Gas filter

4 - Anti-vibration joint

5 - Gas electrovalve

6 - Cut-off valve

EXAMPLE OF GAS INTAKE SYSTEM

Before installation it is advisable to clean the inside

of the fuel intake pipe thoroughly, in order to remove

any residues that could stop the boiler from operating

smoothly.

If you notice the smell of gas:

a) Do not work the electrical switches, the telephone

or any other object that can generate sparks;

b) Immediately open doors and windows to create an

air current that purifies the room;

c) Close the gas valves;

d) Seek the assistance of professionally authorised

company.

In order to prevent any gas leaks it is advisable to install

a surveillance and protection system composed of a gas

leak detector combined with a cut-off electrovalve on

the fuel supply line.

EXTERIOR OF

THE HEATING

CONTROL UNIT

INTERIOR OF

THE HEATING

CONTROL UNIT