SE2L User’s Manual (SE9Z-B1865)

25

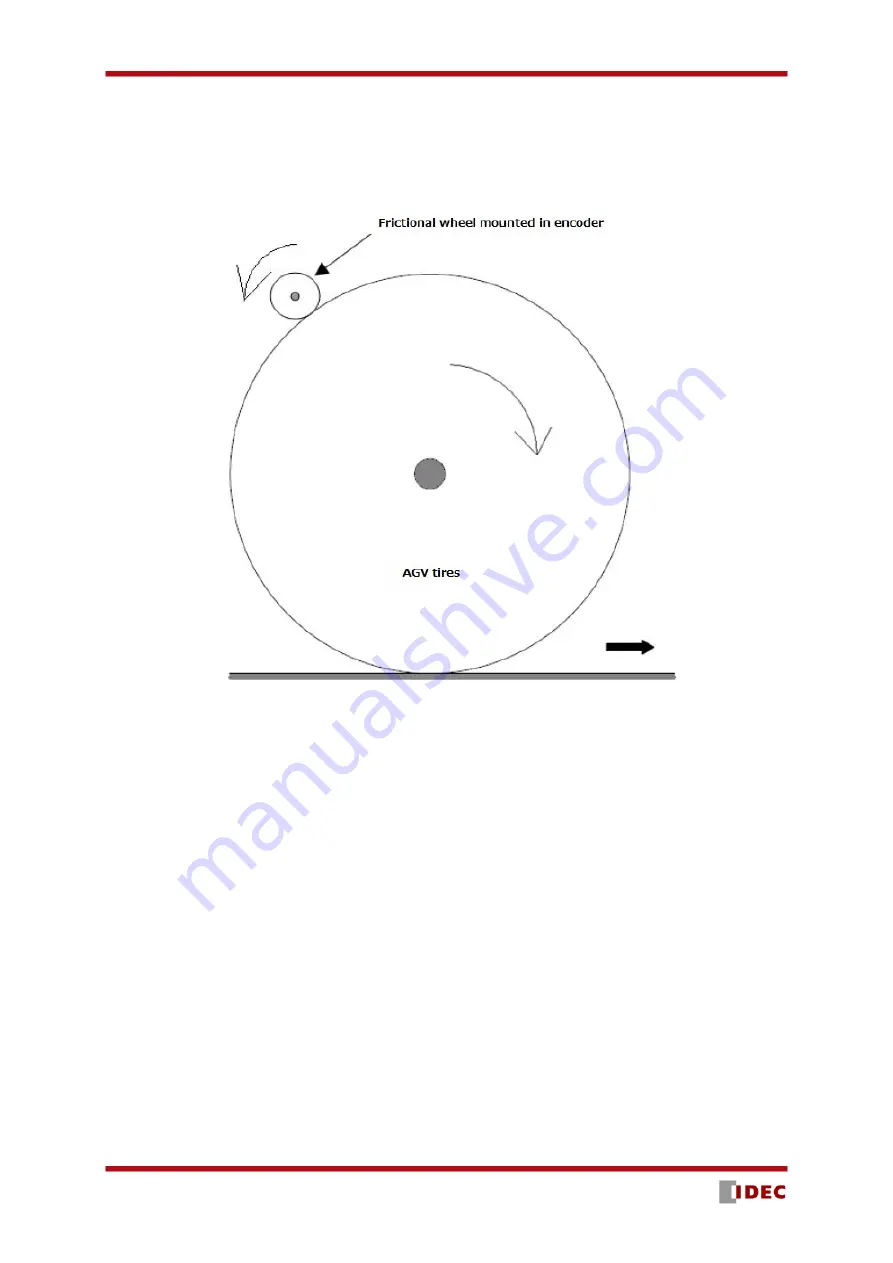

3.6.1 Pulse per cm travel generated by incremental encoders

When AGV travels, increment encoder generates pulses due to the transmission ratio between AVG tires

and increment encoder frictional wheel. Pulse count per cm depends on AGV's speed.

Figure 3-11 Calculation of pulse count for per centimeter travel

AGV tire diameter : 40 cm

Frictional wheel diameter mounted in increment encoder: 5 cm

Increment encoder pulse number per revolution : 1000 pulse

AGV tire circumference = Diameter × Circumference ratio = 40 cm × 3.14 = 125.6 cm

AGV tire's one rotation is equivalent to 8 rotation of frictional wheel. This equals to the 8,000 pulse of

increment encoder.

From above, increment encoder pulse count per cm is obtained as

8,000/125.6 = 63.7

While setting encoder parameters (Encoder Pulse1 and Encoder Pulse2) in SLS Project Designer, set the

encoder pulse count after rounding the calculated value to nearest whole number (64 in this case).

In the explanation above, the transfer method of the rotation was based on the frictional wheel. Same

method can be applied for other cases to estimate the pulse count generated for one rotation of the wheel.

Summary of Contents for SE2L-H05LPC

Page 1: ...SE9Z B1865 SE2L Series Safety Laser Scanner User s Manual...

Page 100: ...SE2L User s Manual SE9Z B1865 99 Figure 7 31 b Function Figure7 31 c Area...

Page 143: ...SE2L User s Manual SE9Z B1865 142 13 External dimension 13 1 SE2L H05LP mm...

Page 144: ...SE2L User s Manual SE9Z B1865 143 13 2 SE2L H05LPC mm...

Page 145: ...SE2L User s Manual SE9Z B1865 144 13 3 Base mounting bracket mm...

Page 146: ...SE2L User s Manual SE9Z B1865 145 13 4 Rear mounting bracket mm...

Page 147: ...SE2L User s Manual SE9Z B1865 146 13 5 Simple base mounting bracket mm...

Page 149: ...SE2L User s Manual SE9Z B1865 148 13 7 Simple rear mounting bracket Long type mm...

Page 150: ...SE2L User s Manual SE9Z B1865 149 13 8 Cover Protection Bracket mm...