ICP DAS PMC/PMD Series User Manual

155

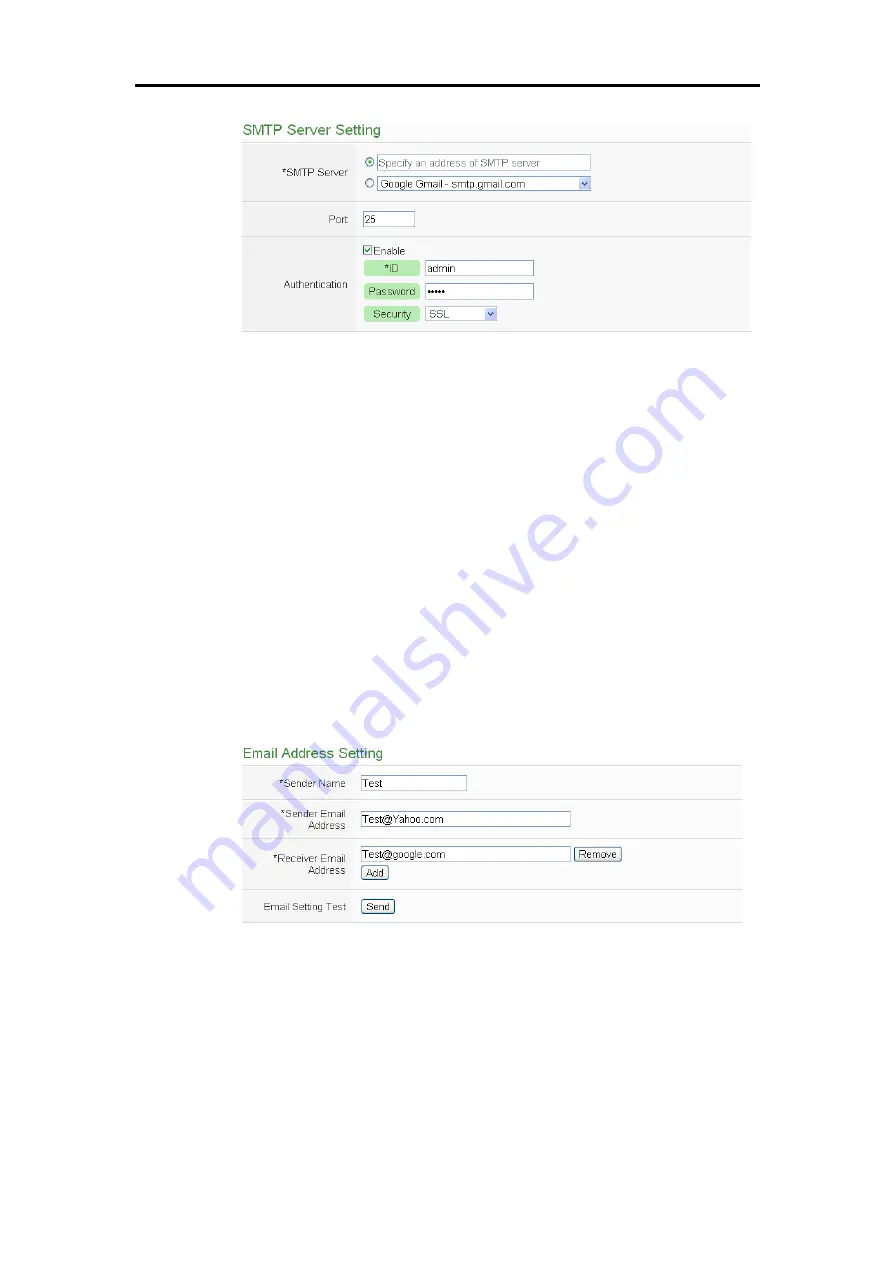

Figure10-3 :

Email setting page(SMTP Server)

iv

Input the Port number, the default port number is set as 25.

v

If the SMTP server requires account and password validation, please

select the “Enable” checkbox, and continue steps vi~viii to login into

the SMTP server. If the SMTP server doesn’t need account and

password validation, uncheck the “Enable” checkbox and go directly to

step ix.

vi

Enter the SMTP server login ID in the “Login ID” field.

vii

Enter the SMTP server password in the “Password” field.

viii

In the “Security” field, select the security setting to be “No Security”,

“TLS”, or “SSL” from the dropdown list.

ix

After complete SMTP server setting, continue to input Email address

setting. In the “Sender Name” field, input the name of the sender. The

Email Address Setting page is shown as below:

Figure10-4 :

Email setting page(Email Address)

x

Enter the sender’s email address in the “Sender Email Address” field.

xi

In the “Receiver Email Address” section, click on “Add” to add the

receiver’s email address. At least one email address has to be entered.

xii

To verify whether your email setting is correct to send the Email, click

“Send” in the “Email Setting Test” section, then PMC/PMD will send a

test Email to the receiver’s email address.

Summary of Contents for PMC series

Page 1: ...ICP DAS PMC PMD Power Meter Concentrator Series User Manual Version 3 1 8...

Page 51: ...ICP DAS PMC PMD Series User Manual 38 Figure5 32 Energy Usage Breakdown by Circuit Group Chart...

Page 72: ...ICP DAS PMC PMD Series User Manual 59 Figure6 11 Security setting interface of VPN function...

Page 165: ...ICP DAS PMC PMD Series User Manual 152 The Import of MQTT Topic...