Operation

3-17

ImageTracDS 1210/1155 User’s Manual

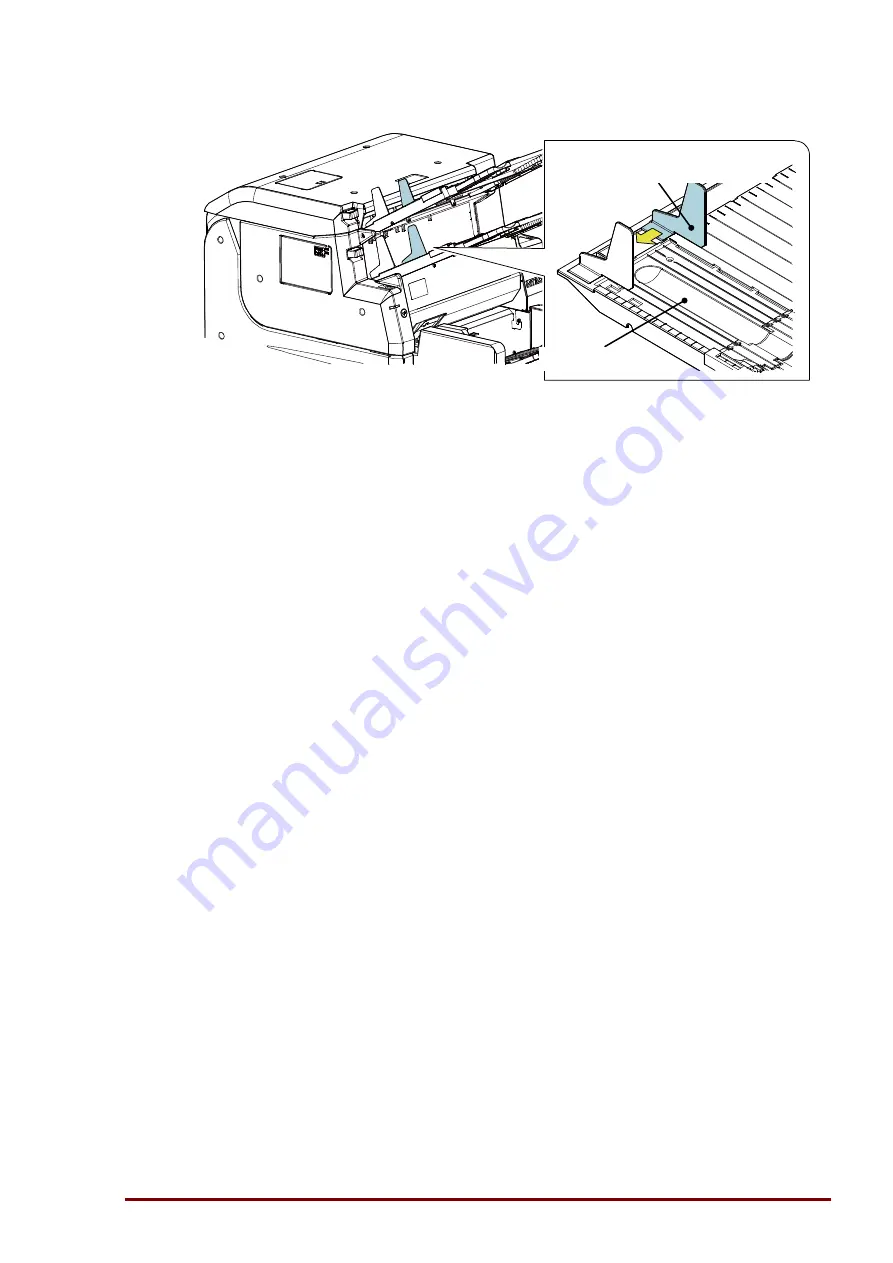

4. Adjust the Output Tray Guides to slip width.

5. Start scanning from the application program.

Do not add papers during scanning.

6. Remove the scanned papers from the Output Tray.

3.4.3 Automatic Scanning and Input Tray Position

This section explains Automatic Scanning and Input Tray Position settings those are suited to

scanning small amount of documents repeatedly.

Automatic Scanning

When "Automatic Scanning” is selected, a scan is started automatically when a sheet is set in

the Input Tray.

1. Start scanning on the application program.

2. Set documents into the Input Tray then a scan is started automatically.

If you have more documents to scan, set those into the Input Tray repeatedly.

3. Automatic Scanning is terminated from the application program.

Or you can terminate Automatic Scanning by a long press of the Operation Button.

4. Remove the scanned papers from the Output Tray.

Input Tray Position settings

“Input Tray Position” parameter on feeding settings of the host application specifies the Input

Tray position.

Normal:

Descends to a bottom

Level 1: 5 mm descent

Level 2: 15 mm descent

Output Tray

Output Tray Guide

Summary of Contents for ImageTracDS 1210

Page 1: ...ImageTracDS 1210 1155 User s Manual Version 1 1...

Page 35: ...1 18 Overview ImageTracDS 1210 1155 User s Manual...

Page 39: ...Installation 2 4 ImageTracDS 1210 1155 User s Manual...

Page 75: ...Operation 3 36 ImageTracDS 1210 1155 User s Manual...

Page 121: ...Maintenance 4 46 ImageTracDS 1210 1155 User s Manual...

Page 122: ......

Page 123: ......