INSTALLATION AND OPERATION INSTRUCTIONS

5-10

SL 20-115 G2 MODULATING GAS BOILER

SL 10-85 G3, SL 14-115 G3, SL 20-160 G3, SL 30-199 G3 MODULATING GAS BOILERS

5.3.4 Temperature Problems

SYMPTOM

DIAGNOSIS

REMEDY

INSUFFICIENT HEAT

Operating temperature

too low.

Increase temperature target.

Priority parameters

or load configuration

improperly set up.

Review load configuration parameters.

Unit undersized.

Refer to Load Calculation vs. Boiler Output.

Air trapped within

system.

Bleed system as required.

Improper system

piping.

Refer to recommended piping in

Section 1.6

System pump

undersized.

Check pump manufacturer’s data/check temp

differential across heat exchanger.

Poor gas/air mixing.

Check CO

2

level.

Defective thermostat.

Refer to manufacturer’s instructions.

Obstruction in

condensate drain.

Inspect and clean condensate drain.

Unit cycling on

operating/ safety

controls.

Check operation with Ohmmeter/Voltmeter.

System radiation

undersized.

Check manufacturer’s rating tables for capacity per

foot.

TEMPERATURE EXCEEDS

THERMOSTAT SETTING

Incorrect anticipator

setting.

Check with Ammeter.

Thermostat not level.

Check level.

ONE OR MORE ZONES DO

NOT HEAT PROPERLY

Air trapped within

zone(s) piping

Vent system/zone as required.

Insufficient radiation/

excessive heat loss.

Check actual length of pipe using radiation / heat loss

calculation.

Insufficient flow rate to

zone(s).

Check temperature drop across zone.

Defective zone valve/

zone circulator.

Check operation per manufacturer’s instructions.

Summary of Contents for SL 20-160 G3

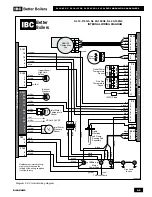

Page 75: ...6 3 DIAGRAMS SL 10 85 G3 SL 14 115 G3 SL 20 160 G3 SL 30 199 G3 MODULATING GAS BOILERS...

Page 77: ...6 5 DIAGRAMS SL 10 85 G3 SL 14 115 G3 SL 20 160 G3 SL 30 199 G3 MODULATING GAS BOILERS...

Page 79: ...6 7 DIAGRAMS SL 10 85 G3 SL 14 115 G3 SL 20 160 G3 SL 30 199 G3 MODULATING GAS BOILERS...

Page 85: ...SERVICE RECORD DATE LICENSED CONTRACTOR DESCRIPTION OF WORK DONE...

Page 86: ...NOTES...

Page 87: ...NOTES...