INSTALLATION AND OPERATION INSTRUCTIONS

1-20

SL 10-85 G3, SL 14-115 G3, SL 20-160 G3, SL 30-199 G3 MODULATING GAS BOILERS

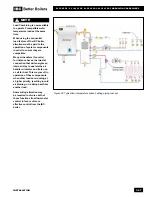

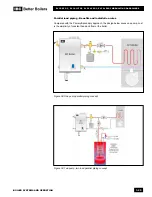

SL 10-85 G3, SL 14-115 G3, SL 20-160 G3, SL 30-199 G3 MODULATING GAS BOILERS

1.6 WATER PIPING

1.6.1 General Piping Issues

The SL boilers were designed to be easy to install in almost any application. Its unique

multi-port piping design allows connection from either side or both sides at once.

Primary/secondary piping, or the use of a hydraulic separator is recommended for

maximum flexibility in multi-load applications, but piping loads in parallel is also

encouraged in systems that only have two loads, or when loads are operating

simultaneously. The extremely low pressure drop through the SL Series heat exchanger

allows many options not available in other designs. In short – IBC has built a boiler that

will allow you to pipe the system the way you prefer, rather than try and dictate your piping

practices from boiler to radiator.

There are some important details to consider however, and this section of the Installation

and Operating Manual will walk you through them so you can enjoy a trouble-free

installation.

Figure 26: Overview of piping options

Summary of Contents for SL 20-160 G3

Page 75: ...6 3 DIAGRAMS SL 10 85 G3 SL 14 115 G3 SL 20 160 G3 SL 30 199 G3 MODULATING GAS BOILERS...

Page 77: ...6 5 DIAGRAMS SL 10 85 G3 SL 14 115 G3 SL 20 160 G3 SL 30 199 G3 MODULATING GAS BOILERS...

Page 79: ...6 7 DIAGRAMS SL 10 85 G3 SL 14 115 G3 SL 20 160 G3 SL 30 199 G3 MODULATING GAS BOILERS...

Page 85: ...SERVICE RECORD DATE LICENSED CONTRACTOR DESCRIPTION OF WORK DONE...

Page 86: ...NOTES...

Page 87: ...NOTES...