New R-Line Refuse Collection Micro

User Manual RCM10

22

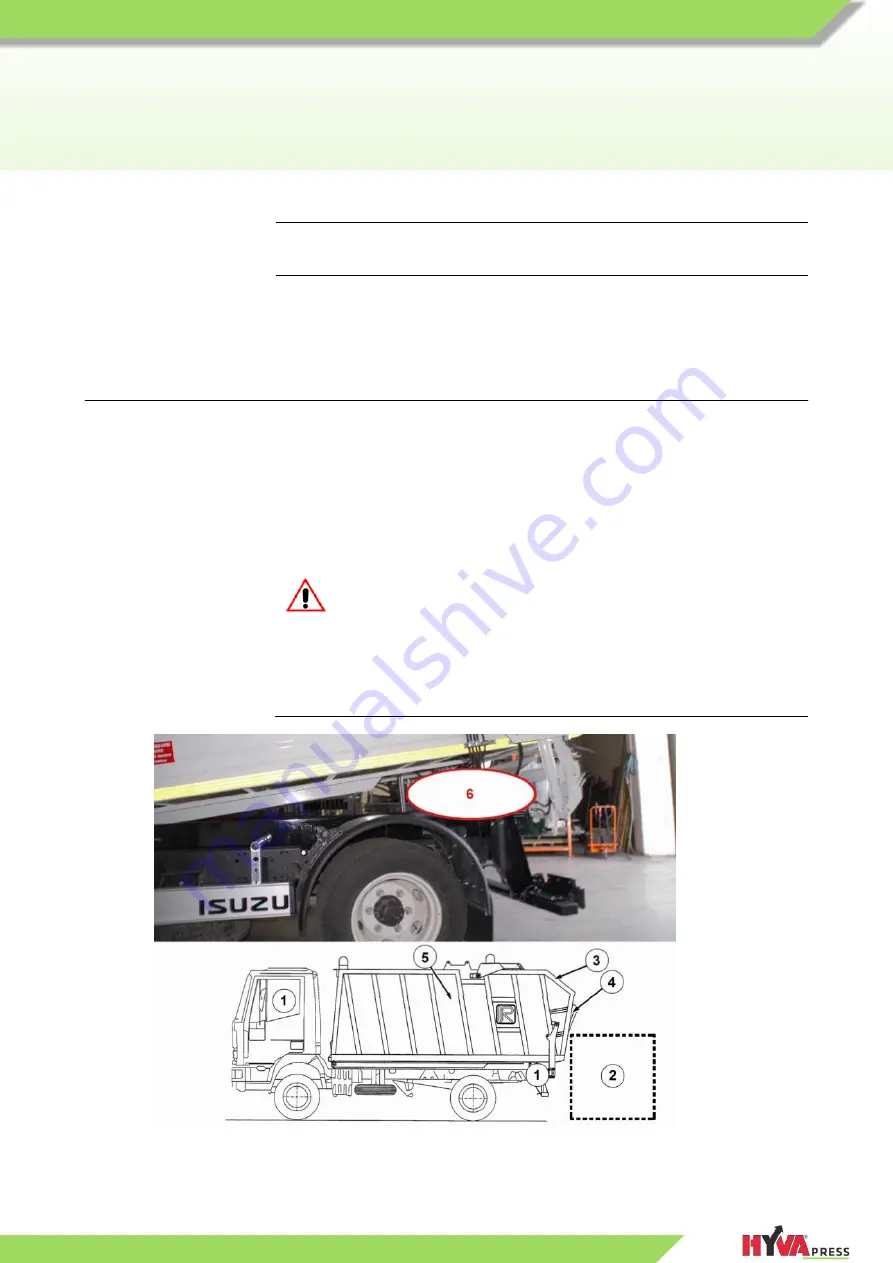

3.7.1 Work areas and dangerous areas

Introduction

The work areas and dangerous areas are described below.

Work areas

The diagram in figure 3-1 indicates the work areas, the main command

areas, and the dangerous areas.

Work areas:

1) Operator command and control area;

2) Operator area for loading/unloading bins.

Dangerous areas

Dangerous areas:

3) The area inside the collection container, where the compacting

shovel functions;

4) The bin lifting and tipping area;

5) The movement area (inside the protection guards on both sides of

The tank) of the hydraulic arms that move the compacting shovel;

6) The area below the raised collection tank.

ATTENTION

The term "dangerous area" also includes:

• All the work areas inside the machine;

• All the areas protected by the special protection guards.

Fig.3 - 1