2.

Connect a crane [the capacity of the crane must

be at least 681 kg (1501 lb)] to the lifting eye on

the sideshift carriage. See Figure 12.

3.

Remove the two upper capscrews from the

lower apron. Slowly loosen the two bottom cap-

screws, but do not remove them. The slotted

holes will allow the lower apron to move down

so the sideshift carriage can be removed.

4.

Carefully lift the sideshift carriage from the

standard carriage. The sideshift cylinder sup-

port bracket and cylinder will stay on the

standard carriage. Remove the bearings.

WARNING

Always wear the proper protective equipment in-

cluding eye protection and petroleum-resistant

gloves when handling hydraulic oil. Thoroughly

wash oil from exposed areas of skin as soon as

possible.

The hydraulic oil is hot at normal operating tem-

peratures. Be careful when draining the oil.

Never check for leaks by putting hands on hy-

draulic lines or components under pressure. Hy-

draulic oil under pressure can be injected into the

skin.

CAUTION

Protect the hydraulic system from dirt and con-

taminants when servicing the hydraulic system.

5.

Disconnect the hydraulic lines at the sideshift

cylinder. Put caps on the open hydraulic lines.

Remove the cylinder support bracket from the

standard carriage. If necessary, remove the

threaded rods and shims in order to remove the

sideshift cylinder.

STANDARD CARRIAGE AND HANG-ON

SIDESHIFT CARRIAGE, REPAIR

NOTE:

The carriage can have four or six load roll-

ers. When the carriage has four load rollers, shims

are used behind all of the load rollers. When the

carriage has six load rollers, shims are installed on

the bottom and middle rollers only.

1.

If any of the load rollers must be replaced,

make a note of the location and number of the

shims. Install the shims, load rollers, and snap

rings. See Carriage Adjustments for correct ad-

justment of the load rollers.

2.

If the carriage aprons have any protruding

welds or damaged notches, repair by grinding,

filing, or welding.

3.

The repair procedure for the sideshift cylinder

is as follows (see Figure 12 and Figure 13):

a.

Remove the retainers from the shell. Pull the

rod from the shell.

b.

Replace seals, O-rings, or backup rings as

necessary. Use the installation guides to pre-

vent damage to the seals.

c.

Lubricate all internal parts with clean hy-

draulic oil.

d.

Install the piston and rod in the shell. Apply

Loctite

®

242 to the threads of the retainers.

Install the retainers and tighten them to

27 N•m (20 lbf ft).

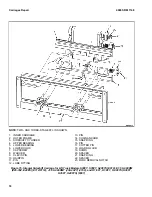

1. SHELL

2. O-RING

3. BACKUP RING

4. ROD SEAL

5. RETAINER

6. WIPER

7. PISTON AND ROD

8. PISTON SEAL

Figure 13. Sideshift Cylinder

Carriages Repair

4000 SRM 1148

14