CAUTION

Remove fork latch pins if adding a fork positioner

attachment. Damage to forks and other carriage

components can occur if fork latch pins are not

removed prior to using attachment.

NOTE:

Forks are to be replaced in sets, not indi-

vidually, by trained personnel only.

1.

Move carriage into position to install forks.

2.

Use lifting device and slide forks onto fork car-

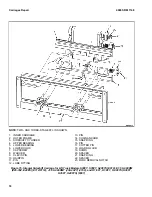

riers. See Figure 7.

NOTE:

Install fork carrier blocks and retainer cap-

screws in hole positions on fork carriers as noted

during removal.

3.

Install fork carrier blocks and retainer cap-

screws in hole positions on fork carriers as no-

ted during removal.

4.

Tighten

retainer

capscrews

to

100 N•m (75 lbf ft).

NOTE:

DIMENSIONS SHOWN ON BOTTOM OF FORK CARRIERS ARE THE WIDTH OF THE FORK BEING

INSTALLED. THE TWO STAGE LFL CARRIAGE AND THE THREE STAGE FFL CARRIAGE ARE THE SAME.

1. RETAINER CAPSCREW

2. FORK CARRIER

3. FORK CARRIER BLOCK

Figure 7. Hole Location, Fork Mounting on Fork Carriers

CHECKS, LIFT TRUCKS NOT EQUIPPED

WITH FORK POSITIONER OR EQUIPPED

WITH FORK POSITIONER BEFORE

AUGUST, 2012

WARNING

Never repair damaged forks by heating or weld-

ing. Forks are made of tempered steel using spe-

cial procedures. Always replace damaged forks as

a pair.

1.

Inspect forks for cracks and wear.

2.

Check alignment of fork tips. Difference in

height of fork tips must be less than three per-

cent of fork length. See Table 1 and Figure 8.

Some applications may require closer align-

ment. If forks DO NOT meet specification they

both must be replaced.

Fork Replacement

4000 SRM 1148

8