Fork Replacement

Forks are held on the carriage by hooks and kept in

position by pins inserted through top fork hooks

into slots in top carriage bar. If pin does not remain

engaged in carriage slot, replace with new pin.

On lift truck models not equipped with a fork posi-

tioner attachment, or equipped with a fork posi-

tioner manufactured before August, 2012, forks are

held on the carriage by hooks and kept in position

by pins inserted through the top fork hooks into

slots in top carriage bar. See Figure 4.

CAUTION

Remove fork latch pins if adding a fork positioner

attachment. Damage to forks and other carriage

components can occur if fork latch pins are not

removed prior to using attachment.

The forks are held on the carriage by hooks. Forks

on a standard carriage or an integral sideshift car-

riage not equipped with a fork positioner attach-

ment, are held in position by pins that fit through

the top fork hooks and into slots in the top carriage

bar. If pin does not remain engaged in carriage slot,

replace with new pin. Always check that pins for

forks keep forks in position on carriage. Replace

damaged fork pin parts. Forks are removed from

carriage by aligning forks with fork removal notch.

Fork removal notch is in bottom bar of carriage.

See Figure 4.

Forks used on an integral sideshift carriage equip-

ped with a fork positioner attachment are held in

position with fork carriers (inner and outer) that

slide along the fork positioner cylinder. Depending

on the size and configuration of forks installed on

lift truck, there may be a spacer bar between the

inner and outer fork carriers. See Figure 2. The

forks are removed from the carriage by aligning the

forks with fork removal notch. Fork removal notch

is in the bottom bar of carriage. See Figure 4.

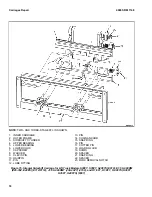

1. OUTER FORK CARRIER

2. CAPSCREW

3. SPACER BAR*

4. INNER FORK CARRIER

*SPACER BAR USED ON 977 mm (38.5 in.) AND

1067 mm (42 in.) CLASS II CARRIAGES.

Figure 2. Fork Carrier Components

REMOVE, LIFT TRUCKS NOT EQUIPPED

WITH FORK POSITIONER OR EQUIPPED

WITH FORK POSITIONER BEFORE

AUGUST, 2012

WARNING

DO NOT try to remove a fork without a lifting de-

vice. Each hook fork for these lift trucks can

weigh 45 to 115 kg (99 to 254 lb).

CAUTION

There are NO pins in forks on lift trucks equipped

with a fork positioner.

NOTE:

Forks are to be replaced in sets, not indi-

vidually, by trained personnel only.

Safety Procedures When Working Near Mast

4000 SRM 1148

4