General Maintenance

Revision C

Reference

6-27

*

(1(5$/

0

$,17(1$1&(

6PDUW7RXFK$QDO\]HDQG5HWULHYH7RRO

HySecurity provides Smart Touch Analyze and Retrieve Tool (START) software to help HySecurity gate

operator users and installers conduct the following field service activities:

•

Configure installer and user menu settings

•

View the operator history (event) log

•

Display monitored inputs for operator diagnostics

•

Load Smart DC Controller (SDC) operator code

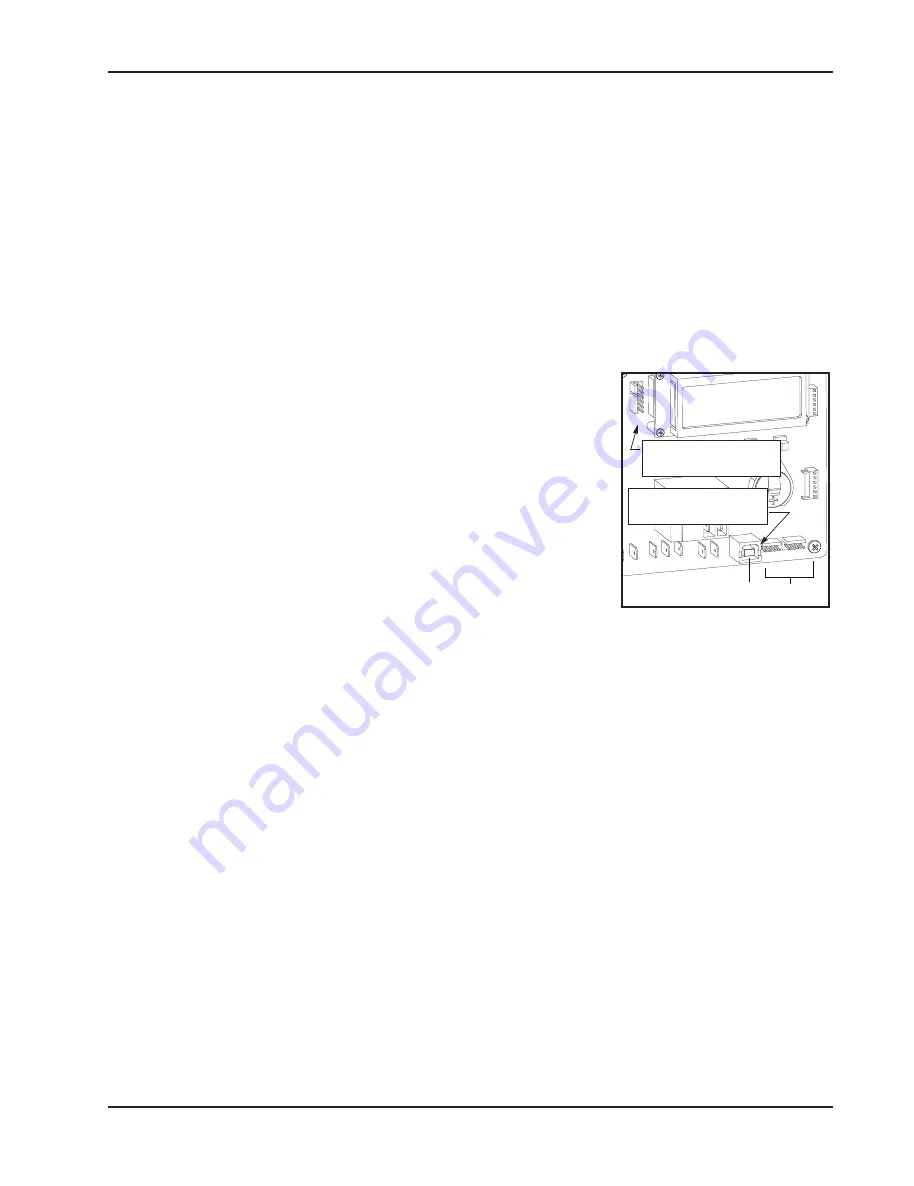

With START software loaded on your laptop computer, you have an

invaluable management tool for all HySecurity operators. Either the USB

port or the RS232 serial port, found on the Smart DC Controller (see

Figure 6-16), allows you to download system diagnostics and upload

system configurations using the START software. The free START

software is conveniently located on the

www.hysecurity.com

website.

Instructions for downloading START are found on the website, as well.

:

+$7

<

28

1

(('

•

Standard USB 2.0 A-B communications cable. If you are using the

HySecurity RS-232 to USB adapter, be sure to install the USB driver

in your laptop.

•

Laptop computer with Windows PC operating system (XP, Vista, or

Windows 7)

•

Minimum 128MB of RAM

•

Minimum 5MB of hard drive disk space

•

VGA graphics card (minimum resolution of 800 x 600)

,

167$//,1*

67$576

2)7:$5(

Read the START User Manual, and then take the following steps to download START software:

1. Bring up your web browser and type in

http://www.hysecurity.com

in the command line.

2. Click

Technical Support

(left column) on the HySecurity home page.

3. Enter your user name and password. If you do not have a user name, register as an online member.

4. Click to Download:

S.T.A.R.T. software for Smart Touch and Smart DC

.

5. Read the End User License Agreement and, if you agree to the terms, click on,

I accept

(bottom of the

page).

6. Click

RUN

. A setup window appears.

OPTIONS

PEN COM

DUAL GATE

COM

B

A

U

S

E

R

2

COM NO

DC

RS-485

COMMUNICATION

USB PORT

USER 1

RS-232

)LJXUH

Connect to RS-232 with

a HySecurity adapter.

If using a USB cable,

connect it to the USB port.

All manuals and user guides at all-guides.com