60 – English

MAINTENANCE AND SERVICE

B

B

B

Mountings

General

•

Check that all components are properly secured by

feeling, pulling etc. Keep a look out for wear damage.

This can be caused by components coming loose.

•

A bolted joint that is secured with adhesive should not

be tightened. Simply check that it is tight. If a glued

bolted joint has come loose, clean the threads before

fresh adhesive is applied.

•

Check the shafts with respect to mounting/locking.

Check expanding shafts by tightening with a torque

wrench.

•

Locking pins must be checked with respect to damage

and mounting.

Shafts

•

The design of the expanding shafts ensures that there

is not too much play provided that they are tightened

regularly. New expanding shafts must be tightened

frequently until they have bedded in. Wear damage on

the expanding shaft’s sleeve is a typical sign that they

have not been tightened correctly or sufficiently often.

•

If an expanding shaft has slipped out of position it is

important that it is centered before being retightened

again.

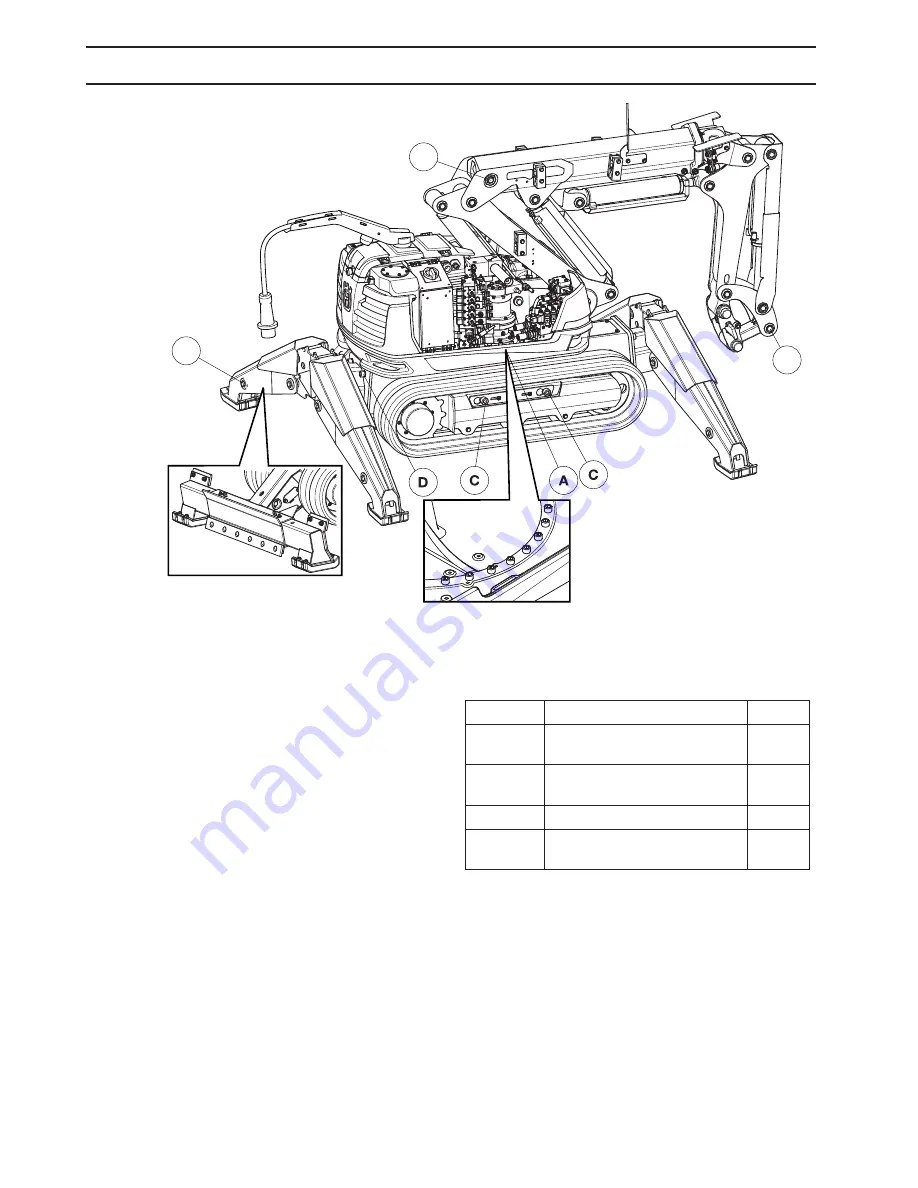

Tightening torque

Use abutment when torquing through shafts to avoid the

shaft rotating.

Position

Nm

A

Gear ring bearing to chassis

beam/bottom plate

81

B

Shafts, arm system, outriggers/

dozer blade

204

C

Track sides

500

D

Support leg bracket (DXR270,

DXR300, DXR310)

650

Summary of Contents for DXR-310

Page 75: ...English 75 TECHNICAL DATA Range and transport diagram DXR250 4483 176 5 2020 79 5 4815 189 5 ...

Page 77: ...English 77 TECHNICAL DATA DXR270 4483 176 1986 78 4849 191 1435 56 ...

Page 79: ...English 79 TECHNICAL DATA DXR300 4868 192 2368 93 5231 206 1818 72 ...

Page 81: ...English 81 TECHNICAL DATA DXR310 5182 204 2129 84 2678 105 5549 218 ...

Page 84: ...1158619 27 z Z 78 z Z 78 2016 12 19 US Original instructions ...