Built on Innovation

®

15

Basic Programming and Setup

MANUAL STARTS AND TEST

On the Home screen, the Manual soft key lets you start

stations, programs, or a Test program. Once you press

Manual, there are three choices:

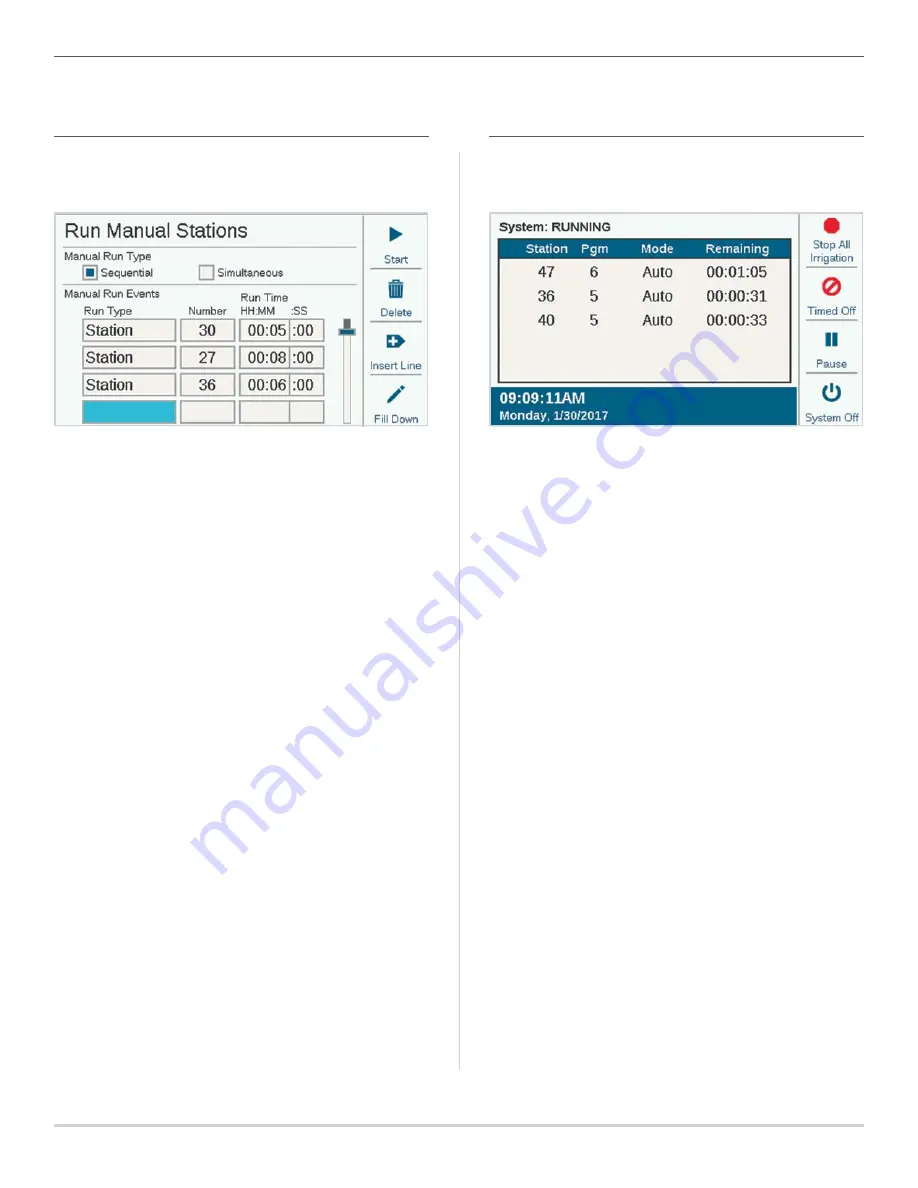

MANUAL STATIONS

Specify one or more stations to run and enter a run time for

them. You can also choose to run them simultaneously, rather

than sequentially, if you check the Simultaneous box. Press

the Start key to start the list.

MANUAL PROGRAM

Select a program number to start, and press the Start key

to start it. It is also possible to scroll down to an event in the

program, and start the program from that point forward.

A Manual Station or Program Start will pause any automatic

watering until the Manual Program has completed.

TEST PROGRAM

The Test program will run all stations in the controller for the

Run Time entered on the screen. It is also possible to specify

a station number, and run all remaining stations from that

number to the highest numbered station.

In the ACC2 Decoder controller, the Test Program will only run

stations that already have a run time in other programs in the

controller.

STOP COMMANDS

Any running irrigation can be stopped immediately from the

Home screen. The top soft key offers the following choices for

stopping irrigation:

STOP ALL IRRIGATION

This immediately stops everything that is watering or running.

The controller is still in Automatic irrigation mode, and will

resume watering at the next start time.

TIMED OFF

Like System Off, this stops all stations and prevents automatic

irrigation, but for a specified period of days. When the

days have counted down to zero, the controller will resume

automatic operations.

PAUSE

This interrupts whatever is currently running, until either

Resume is pressed or 30 minutes have passed. Anything

running will be resumed where it left off, and run for its

remaining time. When items are paused, the Resume button

will appear.

SYSTEM OFF

This turns off all irrigation, and places the controller in

permanent Off mode. No automatic irrigation will occur.