UPS5000-E-(50 kVA-300 kVA)

User Manual (50 kVA Power Modules)

3 Installation

Issue 02 (2017-02-25)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

106

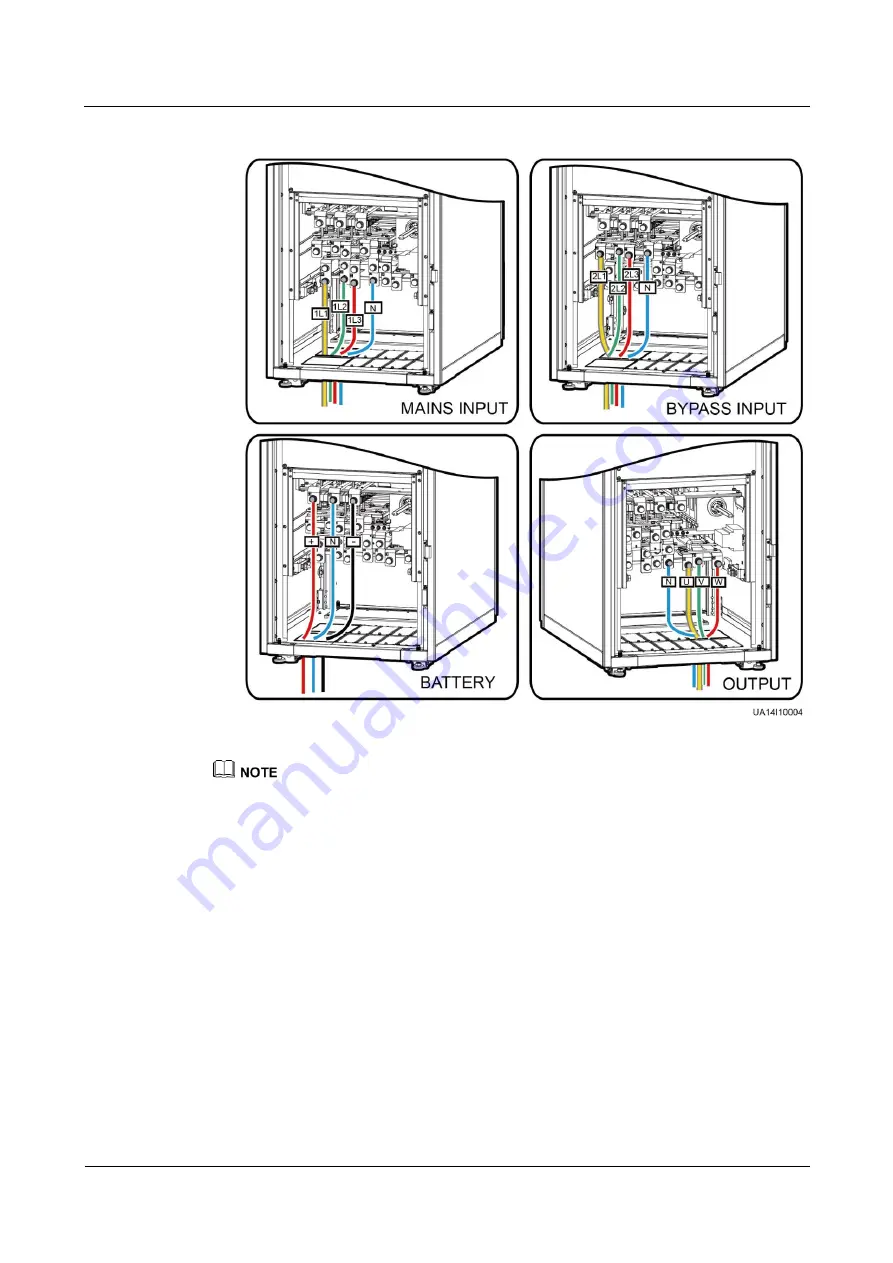

Figure 3-69

Connecting power cables

For details about how to connect the battery neutral wire, see

Single mains

For single mains, the copper bars between the mains and bypass input terminals do not

need to be removed, and bypass input cables do not need to be connected.

Step 5

Route the signal cables on the left sideof subracks along the left side of the cabinet and the

cables on the right side of subracks along the right side of the cabinet, and then bind the

cables to the cabinet, as shown in