TP48200A-HT19C3 and TP48200A-HT19C4 Telecom

Power

User Manual

A Technical Specifications

Issue 03 (2019-11-15)

Copyright © Huawei Technologies Co., Ltd.

84

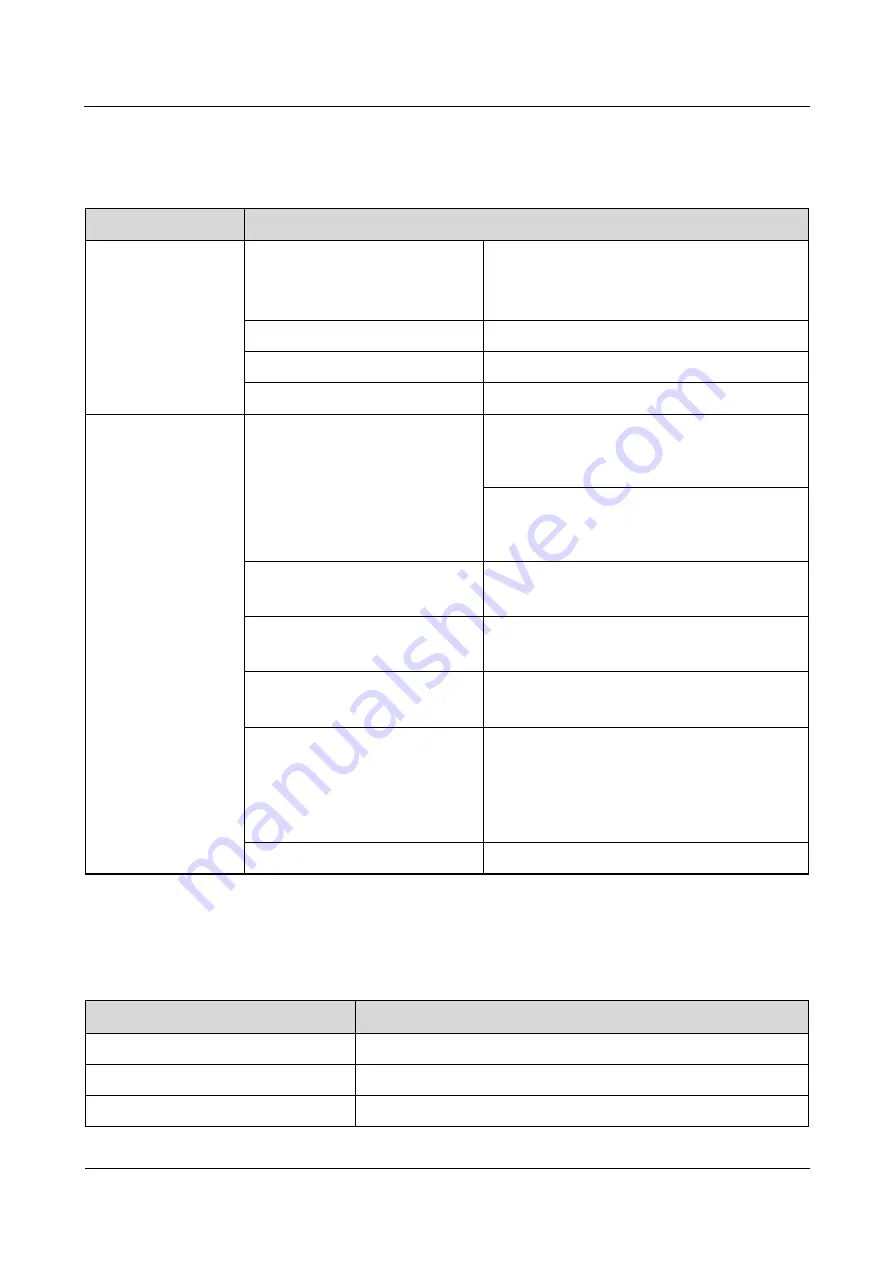

A.3 EMC Specifications

Table A-3

EMC specifications

Item

Specifications

Electromagnetic

interference (EMI)

Conducted emission (CE)

EN55022

AC power port: Class B

DC power port: Class A

Radiated interference

Class B, EN55022

Harmonic current

IEC 61000-3-12

Voltage fluctuation and flick

IEC 61000-3-11

EMS

Electrostatic discharge (ESD)

Shell ports comply with IEC61000-4-2 (criterion

B).

Contact discharge: 6 kV; air discharge: 8 kV

Signal ports comply with IEC61000-4-2

(criterion R).

Contact discharge: 2 kV

Electrical fast transient (EFT)

IEC61000-4-4 (criterion B)

AC power port: 2 kV; DC power port: 2 kV

Radiated susceptibility (RS)

IEC61000-4-3 (criterion A)

10 V/m

Conducted susceptibility (CS)

IEC6100-4-6 (criterion A)

Power port: 10 V; signal port: 3 V

Surge immunity

IEC61000-4-5 (criterion B)

AC power port: differential mode: 2 kV (8/20

us); common mode: 4 kV (8/20 us)

DC power port: differential mode: 2 kV (8/20

us); common mode: 4 kV (8/20 us)

Voltage dips immunity (DIP)

IEC 61000-4-11

A.4 Cabinet Specifications

Table A-4

Cabinet specifications

Item

Specifications

Dimensions (H x W x D)

2030 mm x 820 mm x 760 mm (including the 150 mm high base)

Cabinet weight

≤ 200 kg (excluding rectifiers and batteries)

Protection level

Equipment compartment: IP55