19

Use drive rolls with a groove that matches the wire

diameter chosen. There are different sizes and

shapes of drive rolls. For .023”, .024”, and .025”

diameter wire, use a drive roll marked 0.6; for .030”

wire, use a drive roll marked 0.8; for .035” wire, use

a drive roll marked 0.9 or 1.0; for .045”, .047”, and

3/64” wire, use a drive roll marked 1.2. (

Note:

Some

drive rolls are reversible, meaning there are two

different size grooves on the same drive roll—

simply flip the drive roll so that the marking for the

size you need faces you.)

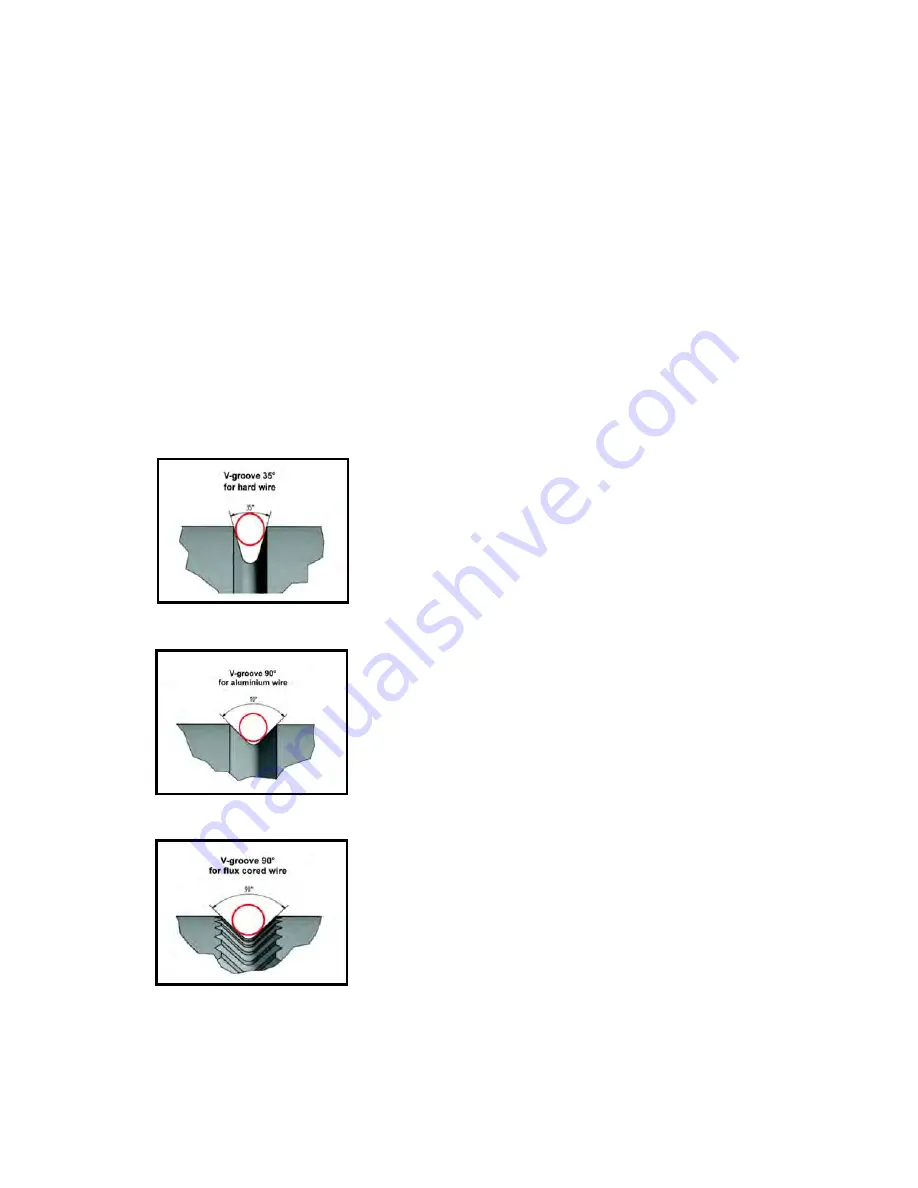

Also, different materials require different drive roll

shapes. For instance, mild steel wire, stainless steel

wire, and silicon bronze wire typically use a

standard V-shaped drive roll (

Fig. 17

). Softer

aluminum wire uses a U-shaped, or V90 degree,

drive roll (

Fig. 18

). Flux-cored wire, whether used

with or without gas, and most hard surfacing wires,

require the use of a knurled drive roll—the little

teeth provide extra traction on these wires (

Fig. 19

).

Fig. 17

Fig. 18

Fig. 19

Use the proper wire tension. When welding with

mild steel or stainless steel, feed tension is important

but a little forgiving. Generally, the wire tension

should be set around 3. If that does not give you

good results, there is most likely a problem

unrelated to wire tension present. For example, a

bad contact tip, a bad liner, a defective welding gun,

etc. can cause the wire to not feed smoothly.

When welding flux-cored wire, then tension should

be set lower than 2. If flux-cored wire is being fed

through a wire feeder with too much tension, the

tubular flux-cored wire will deform and its shape

will change; the wire will become oblong and too

big to fit through the contact tip. Improper electrical

contact, poor weld quality, burned contact tips, and

other issues will follow. Also, over-tightened drive

roll tension and deformed wire will cause metal

particles to separate from the wire. Those particles

will, over time (sometimes a very short time, such as

after welding only several pounds of wire), deposit

themselves in the liner as the wire is transported

through the gun, ultimately clogging the liner and

rendering it useless.

When welding aluminum, the drive roll tension

should be less than, or much less than, 1! Please

make sure that both pressure adjusters are backed

way off. This minimizes the chances of the wire

birds nesting (

Note:

If there is burn back or another

issue that jams the wire feed, the setting should be

so low that the drive rolls slip on the wire rather than

continue to feed—continued feeding results in birds

nesting).

Use the correct polarity. Most MIG wires are welded

DCEP (electrode positive), and there are very few

exceptions to this rule (gasless flux-cored wire and

some specialty hard-surfacing wires are exceptions).

If in doubt, please consult the data sheet that came

with the wire, the box the wire came in, or contact

the distributor you purchased the wire from.

Use the correct welding gun. For welding stainless

steel wire or aluminum wire, a cylindrical gas nozzle

provides better gas coverage.

If welding in synergic or pulse mode, select the

correct material thickness (reduce the material

thickness if you need to fill big gaps or if the

material you are welding is very hot) and observe

the wire manufacturer’s recommended CTDW.

Summary of Contents for Pro Pulse 300

Page 6: ...6 Fig 1...

Page 8: ...8...

Page 31: ...31 Pro Pulse 300 Wiring Diagram...

Page 32: ...32 Pro Pulse 300 Parts Diagram...