18

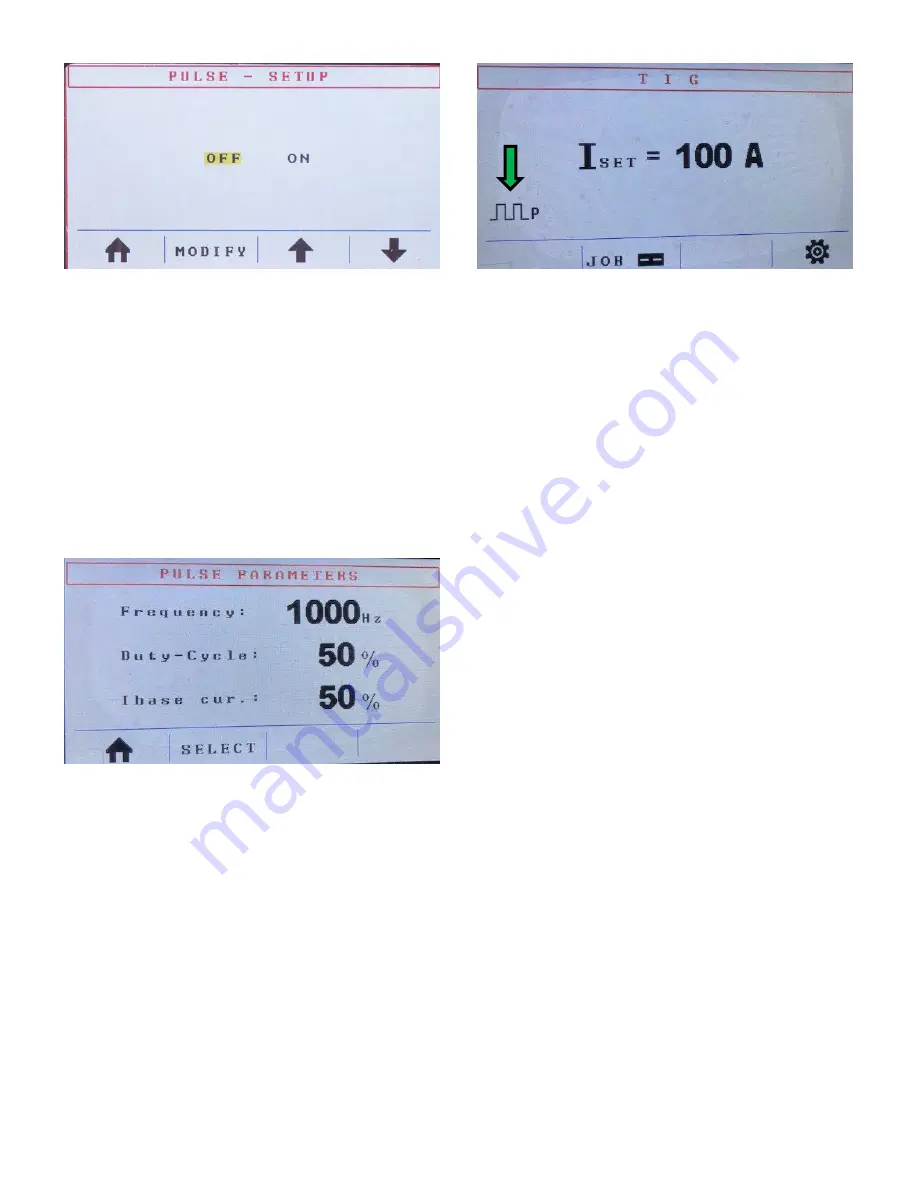

Fig. 14

Press button

E

(

Fig. 4

) again to return to the scr een

where you can turn pulse on or off.

To turn on the pulse function, press button

C

(

Fig. 4;

MODIFY

) and then press button

E

(

the green check

mark

) to confir m.

If you choose to turn pulse on, you will consequently

enter the TIG pulse parameters menu (

Fig. 15

). In the

TIG pulse parameters menu, you can set your frequency

between, as well as set your pulse on time (Duty-Cycle)

and your background current (Ibase Cur.).

Fig. 15

Turning right encoder

G

(

Fig. 4

) will now change the

pulse frequency; you can adjust the pulse frequency

from 0.4Hz to 1000Hz. Adjust your pulse frequency

according to your application needs.

Press button

C

(

Fig. 4; SELECT

) to change the Duty-

Cycle setting, and then press

C

again to change the Ibase

current. Duty-Cycle refers to pulse-on time or the

percentage of time that you weld at peak current (the

previously adjusted welding current) over the

background current. Ibase current, a percentage of the

peak/welding current, refers to the background current.

Fig. 16

The Pulse symbol in

Fig. 16

indicates that the Pro Pulse

300 is now in GTAW-P (pulsed TIG) mode. To turn the

pulse feature off, go back into the advanced pulse

settings menu, and turn the Pulse option OFF.

To weld, attach the ground clamp to the work piece, and

also set the torch on the work piece—allowing the

tungsten to contact the work surface. Next, press and

hold the torch switch or depress the foot pedal

(whichever you are using) and lift the tungsten off the

work piece by about 1/8”. The machine senses that the

tungsten lifted and initiates the arc. Now, the weld can

be made. If a foot pedal or hand control (rotary or slider)

is used, the amperage can be varied while you weld.

When you finish welding, gently lift your finger off the

torch switch or your foot off the pedal to extinguish the

arc.

MIG Welding—General Information

MIG welding with the Pro Pulse 300 can be done three

different ways: manual, synergic, and pulse. In any case,

the following things are critical to making good welds:

Use the correct wire for the material being welded.

Use contact tips that match the diameter of the wire

selected. For example, use .030” contact tips

with .030” wire, use .035” contact tips with .035”

wire, and so on. Follow these instructions for all

wire types, no matter the metal or alloy. However,

on aluminum wire, especially when welding with an

air-cooled MIG welding gun, we strongly

recommend the use of CuCrZr contact tips. If

CuCrZr tips are not available, or a water-cooled

MIG welding gun or push-pull gun is used, standard

tips can be used. The tip size, however, must

be .005” larger than the wire size. For example,

.035” aluminum wire would require a .040” contact

tip, and 3/64” aluminum wire would require a .052”

contact tip. (Note: Using standard contact tips when

welding aluminum results in shorter contact tip life

and limited performance.)

Use the correct gas, at the correct flow rate, for the

wire.

Summary of Contents for Pro Pulse 300

Page 6: ...6 Fig 1...

Page 8: ...8...

Page 31: ...31 Pro Pulse 300 Wiring Diagram...

Page 32: ...32 Pro Pulse 300 Parts Diagram...