lp-666 Rev. 003 Rel. 001 Date 2.25.20

39

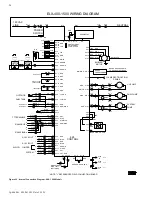

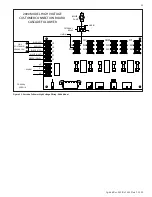

L. Cascade Follower Pump and Sensor Wiring

1. If it is desired to have the boiler control the boiler pump, connect

the Line of an externally provided 120VAC service to the TOP terminal

of the three terminal barrier strip labelled P2 NO (Normally Open).

2. Connect the boiler pump relay COIL Line input to the CENTER

terminal of P2 NO (Normally Open).

3. Connect the Neutral of an externally provided 120VAC service to

the Neutral COIL terminal of the pump relay.

4. Connect the Line of an externally provided 120VAC service to the

NO CONTACT of the pump relay.

5. Connect the NO relay CONTACT to the LINE input of the boiler

pump.

6. Connect the Neutral of an externally provided 120VAC service to

the Neutral input of the pump.

7. Connect the Earth Ground of the externally provided 120VAC to

the Earth Ground input of the pump.

8. If you are using an indirect fired water heater connected directly

to the follower boiler. Connect the Line of an externally provided

120VAC service to the TOP terminal of the three terminal barrier strip

labelled P4 NO (Normally Open).

9. Connect the DHW pump relay COIL Line input to the CENTER

terminal of P4 NO (Normally Open).

10. Connect the Neutral of an externally provided 120VAC service to

the Neutral COIL terminal of the pump relay.

11. Connect the Line of an externally provided 120VAC service to the

Neutral COIL terminal of the pump relay.

12. Connect the other NO relay CONTACT to the LINE input of the

DHW pump.

13. Connect the Neutral of an externally provided 120VAC service to

the Neutral input of the pump.

14. Connect the Earth Ground of the externally provided 120VAC to

the Earth Ground input of the pump.

If desired, an alarm bell or light can be connected to the alarm

contacts of the boiler. The normally closed alarm contact may be

used to turn a device off if the boiler goes into lockout mode. The

alarm contacts are rated 5 amps at 120 VAC.

To connect an alarm device, connect the power for the device to the

center terminal of the three terminal barrier strip labelled ALARM

(P8). Connect the alarm device hot wire to the top terminal of the

three terminal barrier strip labelled ALARM (P8). Connect the neutral

or return of the alarm device to the neutral or return of the power

for the alarm device.

To connect a device that should be powered off during a boiler

lockout condition, follow the same instructions as above and use

the bottom terminal of ALARM NC rather than the top ALARM NO

terminal.

NOTE:

In a cascade system, the alarm output of the boiler addressed

as #1 will activate if any boiler has a lockout condition. The alarm

of boilers addressed #2-15 will only activate if a lockout condition

occurs on that specific boiler.

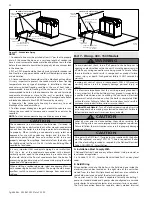

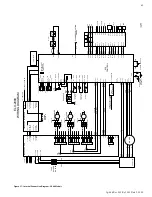

M. Variable Speed Pumping

Variable speed pump support is available on the primary loop of all

models. This feature controls pump speed via an analog 0-10VDC signal

supplied via the 0-10VA connection on the Customer Connection

Board.

When this feature is in use, an installer selected Delta T is maintained

with the Supply and Return sensors, increasing efficiency and providing

better system temperature control. When the difference between the

Supply and Return temperatures is greater than the desired setting,

the pump will increase speed and flow to compensate. Conversely,

if the Delta T is less than the desired setting, the pump will decrease

speed and flow to compensate.

NOTE:

This feature may be used in Primary / Secondary piping

arrangements ONLY!

Variable Speed Pumping Wiring:

1. On the High Voltage Field Connection Board, connect the Line of an

externally provided 120VAC service to the TOP terminal of the three

terminal barrier strip labelled P2 NO (Normally Open).

2. Connect the boiler pump relay COIL Line input to the CENTER

terminal of P2 NO (Normally Open).

3. Connect the Neutral of an externally provided 120VAC service to the

Neutral COIL terminal of the pump relay.

4. Connect the Line of an externally provided 120VAC service to the NO

CONTACT of the pump relay.

5. Connect the other NO relay CONTACT to the LINE input of the boiler

pump.

6. Connect the Neutral of an externally provided 120VAC service to the

Neutral input of the pump.

7. Connect the Earth Ground of the externally provided 120VAC to the

Earth Ground input of the pump.

8. On the Low Voltage Field Connection Board, connect the 0-10v input

wires on the variable speed pump to the terminals marked 0-10VA+

(Positive) and 0-10VA- (Negative).

NOTE:

When making wiring connections, ensure proper polarity or the

system will not operate properly.

5. Connect the other NO relay CONTACT to the LINE input of the

boiler pump.

6. Connect the Neutral of an externally provided 120VAC service to

the Neutral input of the pump.

7. Connect the Earth Ground of the externally provided 120VAC to

the Earth Ground input of the pump.

8. On the Low Voltage Field Connection Board in the front of the

boiler, connect the system pipe sensor to the terminals marked

SYS+ and SYS-.

9. Connect the outdoor sensor (if used) to the terminals marked

OUT+ and OUT-.

6. Connect the signal to start the system to the terminals marked

TT+ and TT-.

NOTE:

This signal can come from a room thermostat or a dry contact

closure. No power of any voltage should be fed into either of these

terminals.

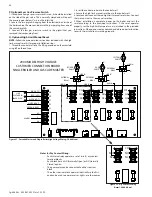

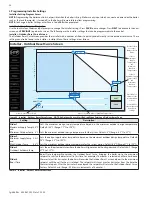

N. Optional 0-10 Volt Building Control Signal

1. A signal from a building management system may be connected to

the boiler to enable remote control. This signal should be a 0-10 volt

positive-going DC signal. When this input is enabled using the installer

menu, a building control system can be used to control the set point

temperature or firing rate of the boiler. The control interprets the 0-10

volt signal as follows; when the signal is between 0 and 1 volts, the

boiler will ignite. As the signal continues to rise towards its maximum

of 10 volts, the boiler will increase in either set point temperature or

firing rate depending on the setting of Function 17 in the Installer

Menu. See this manual for details on the setting of Functions 16 and

17 for this option.

2. Connect a building management system or other auxiliary control

signal to the terminals marked 0-10V+ and 0-10V– on the Field

Connection Board (shown in Figure 35). Caution should be used to

ensure that the 0-10V+ connection does not become connected to

ground.

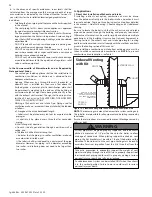

O. Optional High Gas Pressure Switch

1. If an optional high gas pressure switch is used, it should be installed

on the side of the gas valve. This is normally closed and will open if the

pressure goes above 15.5” w.c. on the outlet side.

2. Locate the two pigtails hanging from the electrical box inside of the

boiler cabinet. Remove and discard the jumper plug from one of the

unused pigtails.

3. Connect the high gas pressure switch to the pigtail that you removed

the jumper plug from.