lp-666 Rev. 003 Rel. 001 Date 2.25.20

10

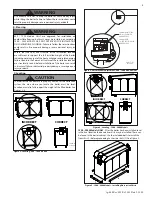

D. Clearances for Service Access

NOTE:

If you do not provide the minimum clearances shown in Figure

6 it might not be possible to service the boiler without removing it

from the space.

NOTE:

A combustible door or removable panel is acceptable front

clearance.

NOTE:

In multiple boiler installations, ensure an 18” minimum clearance

is maintained between boilers.

WARNING

!

The space must be provided with combustion / ventilation air

openings correctly sized for all other appliances located in the same

space as the boiler. The boiler cover must be securely fastened to

prevent the boiler from drawing air from the boiler room. This is

particularly important if the boiler is in a room with other appliances.

Failure to comply with the above warnings could result in substantial

property damage, severe personal injury, or death.

24”

6"

10/31/18

LP-666-M

24"

24"

18"

Figure 6 - Recommended Service Clearances

All boilers eventually leak. Locate the boiler where any leakage from

the relief valve, related piping, tank, or connections will not result

in damage to surrounding areas or lower floors of the building. Any

boiler should be installed in such a manner that if it should leak the

resulting flow of water will not cause damage to the area in which it

is installed. If the boiler is installed in a location where a leak could

cause damage, it is required to provide containment measures.

Such measures include but are not limited to: a properly sized drain

pan installed beneath the boiler and piped to an open drain line, or

installing the boiler on a concrete floor pitched to a free flowing drain.

Failure to provide containment measures is the sole responsibility of

the owner and/or installer. Leakage damages ARE NOT covered by

warranty.

In addition, water leak detection devices and automatic water shutoff

valves are readily available at plumbing supply houses. IT IS HIGHLY

RECOMMENDED BY THE MANUFACTURER TO INSTALL WATER LEAK

DETECTION DEVICES AND AUTOMATIC SHUTOFF VALVES IN ANY

BOILER INSTALLATION WHERE A LEAKAGE OF WATER COULD RESULT

IN PROPERTY DAMAGES.

CAUTION

E. Residential Garage and Closet Installations

Check with your local Authority Having Jurisdiction for

requirements when installing the boiler in a garage or closet.

Please read the entire manual before attempting installation.

Failure to properly take factors such as venting, piping, condensate

removal, and wiring into account before installation could result in

wasted time, money, and possible property damage and personal

injury.

CAUTION

Precautions

If the boiler is located in a residential garage, per ANSI Z223.1:

• Install the boiler burner and ignition devices a minimum of

18” above the floor of the garage. This will ensure the burner

and ignition devices are well off the floor.

• When raising the boiler ensure the entire bottom and fully

filled weight of the boiler are fully supported.

• Locate or protect the boiler so it cannot be damaged by a

moving vehicle.

WARNING

!

The space must be provided with correctly sized combustion/

ventilation air openings for all other appliances located in the

space with the boiler. For power venting installations using room

air for combustion, refer to the venting section, this manual, for

descriptions of confined and unconfined spaces. Do not install

the boiler in an attic. Failure to comply with these warnings could

result in substantial property damage, severe personal injury, or

death.

F. Exhaust Vent and Intake Pipe

The boiler is rated ANSI Z21.13 Category IV (pressurized vent, likely

to form condensate in the vent) and requires a special vent system

designed for pressurized venting.

NOTE: The venting options described here (and further detailed

in the Venting section, this manual) are the lone venting options

approved for this boiler. Failure to vent the boiler in accordance

with the provided venting instructions will void the warranty.

DANGER

!

Failure to vent the boiler properly will result in serious personal

injury or death.

WARNING

!

Do not attempt to vent this boiler by any means other than those

described in this manual. Doing so will void the warranty and may

result in severe personal injury or death.

The exhaust discharged by this boiler may be very hot. Avoid

touching or other direct contact with the exhaust gases of the vent

termination assembly. Doing so could result in severe personal

injury or death.

Vents must be properly supported. Boiler exhaust and intake

connections are not designed to carry heavy weight. Vent support

brackets must be within 1’ of the boiler and the balance at 4’

intervals. Boiler must be readily accessible for visual inspection

for first 3’ from the boiler. Failure to properly support vents could

result in property damage, severe personal injury, or death.

1. Direct Vent of Exhaust and Intake

If installing a direct vent option, combustion air must be drawn

from the outdoors directly into the boiler intake and exhaust must

terminate outdoors. There are three basic direct vent options

detailed in this manual: 1. Side Wall Venting, 2. Roof Venting, and 3.

Unbalanced Venting.

Be sure to locate the boiler such that the exhaust vent and intake

piping can be routed through the building and properly terminated.