lp-666 Rev. 003 Rel. 001 Date 2.25.20

59

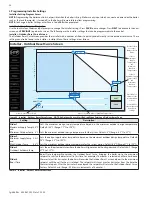

Part 12 - Boiler Monitoring

A. Status Screens

The boiler control has the ability to review system status. To access the Status screens, tap Status in the display Navigation Bar. Tap NEXT or

PREVIOUS to swap between the screens. Tap Home in the display Navigation Bar to exit the Status screens.

Actual Temperatures

Fan Speed Settings

Status

Fan

Maximum Ind/Dir/Voy/Spa

5650

rpm

Maximum Central Heating

5650

rpm

Limit Step Modulation / Cascade

1413

rpm

Minimum

1420

rpm

Ignition

3000

rpm

Setpoint

0

rpm

Actual

95

rpm

PWM

0

%

Check

Off

Configuration

Indirect

5.00

Water Flow

Heat Functions

No demand

Actual Blocking

None

Previous

None

Burner Demand

Off

Burner Function

Stand-by

Lock-Out

Bus Control

Time Stamp

Bic

BIC928

Boiler-Par

FX400BN

Temperature Settings

Supply

137

ºF

Return

87

ºF

Flue

125

ºF

t1/t2

134/137

ºF

t3/t4

125/125

ºF

Indirect

120

ºF

System

89

ºF

Boiler Outdoor

49

ºF

Water Pressure

bar

-

Gl/m

Booster / 0-10V

V

Condensate

Water Level

8

CH / Pool Supply

190

ºF

Indirect/Direct/Voyager/Spa

119

ºF

Indirect Supply

181

ºF

Minimum Supply

32

ºF

DT Pump CH

20

ºF

NEXT

Intern

90

ºF

-

None

-

-

-

-

Bus Master

-

-

-

09:31:10

5-2-18

-

-

0.00

0.0

8

-

-

Tapping the NEXT key advances to Status Screen 2

Status Screen 1

Figure 49 - Status Screen 1

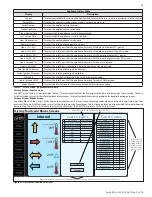

Status Table

Display

Description

Configuration

This is the factory setting of the appliance. It should always read “Indirect”.

Heat Functions

Lets the user know if the appliance is servicing a demand for heat. In this example, there is no demand.

Actual Blocking

This would display a blocking code if the appliance was currently in a blocking state.

Previous

Displays most recent blocking code. In this example, “Tap blocking” was the most recent.

Burner Demand

Will display a demand on the burner. In this example there is currently no demand.

Burner Function

Displays the current burner state. Burner is in stand-by in this example.

Lock-Out

Displays if the appliance is in lockout.

Bus Control

This displays the bus state of the appliance. The appliance in this example is the bus master.

Time Stamp

Displays the time and date.

Bic

Refers to the current control revision. “BIC928” in this example.

Boiler-Par

Refers to the parameter set programmed into the appliance.

Water Pressure

Not Used.

Water Flow

Not Used.

Booster / 0-10V

Displays the voltage on the optional input. This voltage is only relevant if an external 0-10 volt signal is being

used to control the boiler.

Condensate

Not Used.

Water Level

Displays the “electrical resistance” between the LWCO probe, through the water, to ground. A value of 80 and

above indicates a lack of water in the appliance (open circuit). A perfect connection to ground would indicate

a level of 0.

Table 19 - Status Screen 1 - Status Table