lp-666 Rev. 003 Rel. 001 Date 2.25.20

25

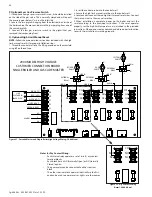

Friction Loss Equivalent in Piping and Fittings

Fittings or Piping

Equivalent Feet

4”

6”

8”

90 Degree Elbow

5’

45 Degree Elbow

3’

Coupling

0’

Air Inlet Tee

0’

One Foot of Straight Pipe

1’

V Series Vent Kit

1’

AL29 4c Vent Terminal

1’

Table 10 - NOTE: Consult Polypropylene venting instructions for friction

loss and pressure drop equivalents.

b. For example: If the exhaust vent is 6” in diameter, has two 90

o

elbows, and 10 feet of PVC pipe we will calculate:

Exhaust Vent Equivalent Length = (2x5) + 10 = 20 feet.

Further, if the 6” intake pipe has two 90

o

elbows, one 45

o

elbow,

and 10 feet of PVC pipe, the following calculation applies:

Intake Pipe Equivalent Length = (2x5) + 3 + 10 = 23 feet.

The total equivalent length is 43 feet, well below the maximum

of 125 feet.

c. Effort should be made to keep a minimum difference in

equivalent length between the exhaust vent and intake pipe.

3. The minimum total equivalent length

is 10 feet for 400 to 1000

models, and 15 feet for 1500 and 2000 models.

Do not exceed the maximum lengths for vent pipes. Excessive

length could result in boiler shutdown and property damage.

CAUTION

F. Exhaust Vent and Intake Pipe Installation

All joints of positive pressure vent systems must be sealed

completely to prevent leakage of flue products into the living

space. Failure to do so could result in property damage, serious

injury, or death.

WARNING

!

1. Use only solid PVC, CPVC, or stainless steel pipe or a Polypropylene

vent system approved for use with Category IV appliances.

ABS pipe material may be used on air intake piping

only

.

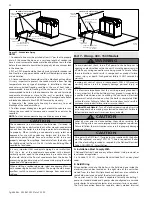

2. Work from the boiler to exhaust vent or intake air termination.

Do not exceed the lengths given in this manual for the vent or air

piping.

3. Cut pipe to the required lengths and deburr the inside and outside

of the pipe ends. Chamfer the outside of each pipe end to ensure

even cement distribution when joining.

Failure to provide the minimum total vent length could result in

property damage and improper product operation.

E. Exhaust Vent and Intake Pipe Sizing

1. The exhaust vent and intake pipe size is 4”, 6”, or 8”, depending on

model.

2. The maximum total equivalent length of exhaust vent and intake

pipe

should not exceed 125 feet for 400 to 1000 models, and

150 feet for 1500 and 2000 models

.

a. The equivalent length of elbows, tees, and other fittings are

listed in the Friction Loss Table.

DANGER

!

Total maximum equivalent length of exhaust vent and intake

pipe must not exceed the lengths defined in this manual. Failure

to keep the total equivalent length below the maximum lengths

determined in this manual will result in faulty boiler operation,

substantial property damage, serious personal injury, or death.

4. When using PVC or CPVC pipe, all joints must be properly cleaned,

primed, and cemented. Use only cement and primer approved for use

with the pipe material. Cement must conform to ASTM D2564 for PVC

and ASTM F493 for CPVC pipe.

NOTE: The use of colored primer is recommended.

NOTE: DO NOT CEMENT POLYPROPYLENE PIPE. Follow

manufacturer’s instructions for proper installation.

NOTE:

Clean and dry the boiler adapters.

DO NOT use primer or cement on the boiler adapters.

a. Clean all pipe ends and fittings using a clean dry rag. (Moisture will

retard curing and dirt or grease will prevent adhesion.)

b. Dry fit piping to ensure proper fit up before assembling any joint.

The pipe should go a third to two-thirds into the fitting to ensure

proper sealing after cement is applied.

c. Priming and Cementing:

i. Handle fittings and pipes carefully to prevent contamination of

surfaces.

ii. Apply a liberal even coat of primer to the fitting socket and to the

pipe end to approximately 1/2” beyond the socket depth.

iii. Apply a second primer coat to the fitting socket.

iv. While primer is still wet, apply an even coat of approved cement

to the pipe equal to the depth of the fitting socket along with an

even coat of approved cement to the fitting socket.

v. Apply a second coat of cement to the pipe.

vi. While the cement is still wet, insert the pipe into the fitting, if

possible twist the pipe a 1/4 turn as you insert it.

NOTE:

If voids

are present, sufficient cement was not applied and joint could be

defective.

vii. Wipe excess cement from the joint removing ring or beads as it

will needlessly soften the pipe.

5. Ensure the vent is located where it will not be exposed to prevailing

winds.

6. In all roof venting applications, exhaust discharge must point away

from the pitch of the roof.

7. If the exhaust vent is to be terminated in a walled off area (such

as a roof with a parapet wall), ensure the exhaust vent terminates a

minimum of 10’ from nearest wall and extends level with or above

the top of the wall. This will ensure flue gas does not get trapped and

possibly recirculated into the intake air pipe, which could contaminate

the combustion air.

8. To prevent water leakage, install adequate roof flashing where the

pipe enters the roof.

9. Do not locate vent over public walkways, driveways, or parking lots.

Condensate could drip and freeze, resulting in a slip hazard or damage

to vehicles and machinery.

10. Due to potential moisture build-up, sidewall venting may not be

the preferred venting option. To save time and cost, carefully consider

venting installation and location.

11. Horizontal lengths of exhaust vent must slope back towards the

boiler not less than ¼” per foot to allow condensate to drain from the

vent pipe.

12. The exhaust vent must terminate where vapors cannot make

accidental contact with people or pets, or damage shrubs or plants.

13. In vacant chimney applications, install and seal a rain cap over

existing chimney openings.

14. All piping must be fully supported. Use pipe hangers at a minimum

of 4 foot intervals to prevent sagging of the pipe where condensate

may form.

15. Do not use the boiler to support any piping.

16. Ensure the outdoor exhaust vent and intake pipe terminations are

screened to prevent blockage caused by debris or birds.

17. Maximum Snow Level Determination: These installation

instructions reference snow levels in establishing a minimum height

for the installation of exhaust vent or air intake terminations. Snow

levels shall be determined as follows:

a. The installation location may, by ordinance, designate how snow

levels are calculated in that location; or