lp-666 Rev. 003 Rel. 001 Date 2.25.20

21

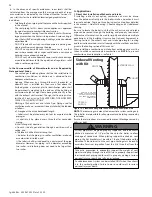

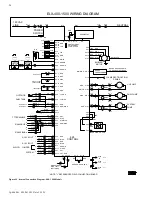

O. Applications*

*NOTE:

Systems shown are

primary/secondary piping

systems. These recommended

systems have a primary (boiler)

loop, and secondary circuits

for heating. The primary loop

and secondary circuits have

separate circulators. The use

of other near boiler piping

configurations could result in

improper flow rates, leading

to inadvertent boiler high limit

shutdowns and poor system

performance.

NOTE:

In piping applications

utilizing a single zone, it

is recommended that the

installer use flow / check valves

with weighted seats at or

near the appliance to prevent

gravity circulation.

FIGURE NOTES:

1. This drawing is meant to

demonstrate system piping

concept only.

2. A mixing valve is

recommended if the DHW

temperature is set above the

factory setting of 119

o

F.

3. Install a minimum of 12

diameters of straight pipe

upstream of all circulators.

4. Install a minimum of 6

diameters of straight pipe up

and downstream of all closely

spaced tees.

5. Piping shown is Primary/

Secondary.

6. The minimum pipe size for

connecting an HTP indirect

fired water heater is 1”.

7. DO NOT down size the boiler

heating loop connections.

8. System flow (Secondary

Loop) must be greater than the

boiler’s Primary Loop flow.

9. Installations must comply

with all local codes.

10. In Massachusetts, a vacuum

relief valve must be installed

on the cold water line per 248

CMR.

11. See Multiple Boiler Manifold

Piping chart, this manual, when

sizing and installing a multiple

boiler system.

WARNING

!

The piping will not support the weight of the circulators. Refer to the circulator manufacturer’s instructions to properly support the circulator.

Failure to comply with these instructions could result in property damage, severe personal injury, or death.

An ASSE 1017 thermostatic mixing valve is recommended on all indirect water heaters if the hot water temperature leaving the heater is

above 119

o

F. Failure to do so could result in substantial property damage, serious injury, or death.

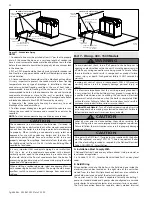

LP-666-C

12/20/18

FROM SYSTEM

TO SYSTEM

BALL VALVE

TYPICAL

AIR SEPARATOR

PURGE VALVE(TYP)

SYSTEM

CIRCULATOR

BACK FLOW

PREVENTER

PRESSURE

REDUCING

VALVE

EXPANSION

TANK

Y-STRAINER

(RECOMMENDED)

MAKE-UP

WATER

BOILER CIRCULATOR

MAY SUBSTITUTE FOR

LOW LOSS HEADER

4 PIPE DIA. SPACING

MAXIMUM

DHW CIRCULATOR

PRESSURE GAUGE

INDIRECT

TANK

CHECK VALVE

CHECK

VALVE

CHECK VALVE

Figure 11 - Single Boiler Space Heating with Indirect Priority

LP-666-D

12/20/18

FROM SYSTEM

TO SYSTEM

BALL VALVE

TYPICAL

AIR SEPARATOR

PURGE VALVE

SYSTEM CIRCULATOR

BACKFLOW

PREVENTOR

PRESSURE

REDUCING VALVE

EXPANSION

TANK

Y-STRAINER

RECOMMENDED

BOILER CIRCULATOR

BALL

VALVE

MAKE-UP

WATER

SYSTEM SENSOR

DHW CIRCULATOR

MAY SUBSTITUTE FOR

LOW LOSS HEADER

4 PIPE DIA. SPACING MAX

PRESSURE GAUGE

BOILER CIRCULATOR

INDIRECT

TANK

CHECK VALVE

CHECK VALVE

Figure 12 - Cascaded Boilers with Indirect Priority on One