lp-666 Rev. 003 Rel. 001 Date 2.25.20

66

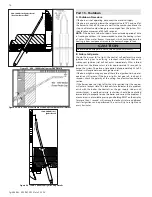

Part 13 - Troubleshooting

Unresponsive Screen -

Ensure the screen is not installed too tightly into the housing, as the screen may be recording a continuous touch at

the edges. Turn the boiler power off at the main power supply and loosen the screen slightly by backing out the nuts behind the housing. If

the problem persists calibrate the screen. See below.

Touchscreen Calibration -

Turn the power switch off at the boiler. While touching the screen with one finger turn the power back on. The

screen will go into calibration mode. Follow the instructions on the screen to complete calibration.

NOTE:

If any sensor detects an abnormal condition or an internal component fails during the operation of the boiler, the display may show

an blocking or fault message and code.

IMPORTANT:

If you see blocking or fault codes on your display readout, call a technician immediately. The message may indicate a more

serious problem will occur soon.

A. Blocking

A Blocking message and code may be the result of a condition that must be manually corrected or by a temporary condition that will resolve

itself.

The boiler control will be operable. The center pane of the Home Screen will be

Orange

and the “

Blocking

” message will display. When the

condition is corrected or corrects itself the display will revert to its normal readout and operation. Be sure to observe the operation of the unit

for a period of time to ensure correct operation and no reoccurrence of the code.

The controller will display a blocking code and message when a blocking condition occurs. These codes, descriptions, and recommended

corrective actions are described in Section C.

B. Fault (Lockout)

A Fault (Lockout) message and code is the result of a condition that the control has evaluated as not safe to restart the boiler. In this case, the

boiler control will be locked out. The center pane of the Home Screen will be

Red

and the “

Lockout

” message will display. The alarm output

will also activate. Most fault conditions cause the CH pump to run in an attempt to cool the boiler.

The controller will display a fault code and message when a lock-out condition occurs. These fault codes, descriptions, and recommended

corrective actions are described in Section C.

After the fault condition has been repaired by a qualified technician press and hold RESET on the display for more than 1 second to clear the

fault and resume operation. Be sure to observe the operation of the unit for a period of time to assure correct operation and no reoccurrence

of fault message.

If overheating occurs or the gas supply fails to shut off, do not turn off electrical power to the circulating pump. This may aggravate the

problem and increase the likelihood of boiler damage. Instead, shut off the gas supply to the boiler at the gas service valve. Failure to do so

may result in property damage, personal injury, or death.

WARNING

!

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN SUBMERGED IN WATER.

Immediately call a qualified service technician. The

appliance MUST BE replaced if it has been submerged. Attempting to operate an appliance that has been submerged could create numerous

harmful conditions, such as a potential gas leakage causing a fire and/or explosion, or the release of mold, bacteria, or other harmful

particulates into the air. Operating a previously submerged appliance could result in property damage, severe personal injury, or death.

NOTE:

Appliance damage due to flood or submersion is considered an Act of God, and IS NOT covered under product warranty.

When servicing or replacing components that are in direct contact with boiler water, be certain that:

• There is no pressure in the boiler. (Pull the release on the relief valve. Do not depend on the pressure gauge reading.

• The boiler water is not hot.

• The electrical power is disconnected.

• The gas is shut off.

Failure to make these checks could result in substantial property damage, serious personal injury, or death.

Label all wires prior to disconnecting them when servicing the boiler. Wiring errors can cause improper and dangerous operation. Failure to

follow these instructions may result in property damage or personal injury.

NOTE:

If system return temperatures are maintained below the dew point, condensation will form on the boiler cabinet and cause some

components to rust.

Code

Message

Description

Possible Remedy

F00

ECO 1 Water

F00 indicates the water in the boiler has

overheated. The boiler will not restart until it

cools sufficiently and a technician determines

and repairs the cause of overheating and

pushes

RESET

on the display. This is a serious

safety issue as indicated by the illuminated red

light and the word LOCKOUT flashing on the

display. During this lockout fault, the pump

will be on in an effort to cool the boiler down.

1. Check circulator pump operation.

2. If the circulator pump is running, ensure there is water in

the system and that the water is moving through the system as

intended. Ensure that all correct ball valves and or zone valves are

open or closed as intended.

3. Observe the temperature/pressure gauge. If the water is not too

hot and this message is displayed, check the wiring to the water

ECO sensor and repair if necessary. If the wiring is ok and this code

is still present and the water is not excessively hot, replace the ECO

sensor.

C. User Interface Display

Lockout Codes