NOTICE:

This drawing is the property of Hi Performance Electric Vehicle Systems Inc., and/or its subsidiaries and affiliates (individually

and collectively “HPEVS”), and contains highly proprietary, confidential, and trade secret information of HPEVS. The recipient of this

drawing agrees (a) to use the information contained herein for the purpose for which it was furnished by HPEVS (b) to return this drawing

upon HPEVS request. This notice shall appear on any complete or partial reproduction of this drawing.

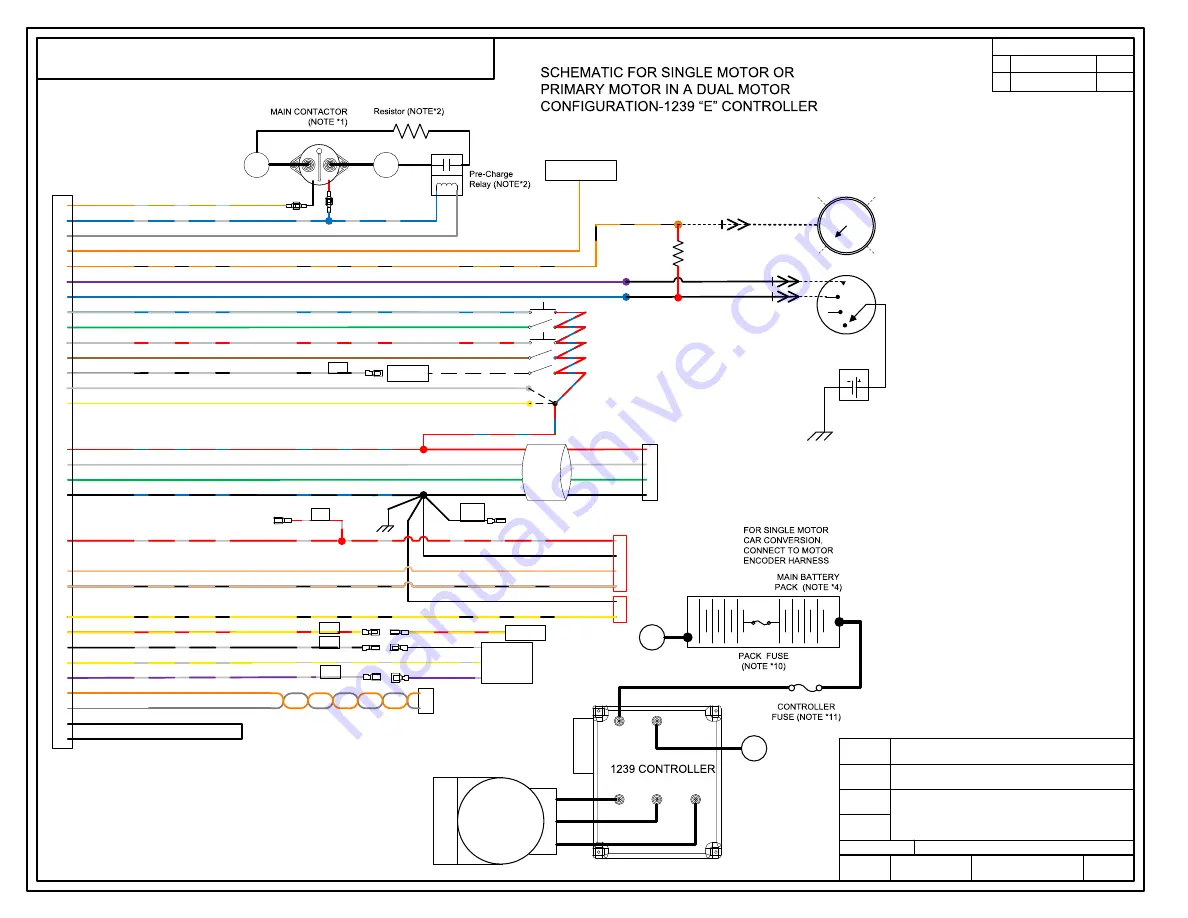

ORANGE/ WHITE 20 AWG

I/O GROUND

PEDAL INTERLOCK

12V POWER CNTRL

5V POWER CNTRL

TX SERIAL

RX SERIAL

ENCODER PHASE A

ENCODER PHASE B

REVERSE

KSI

MAIN CONTACTOR

COIL RETURN

BLUE 20 AWG

BLACK/ BLUE 20 AWG

GREEN 20 AWG

BLUE/ WHITE 20 AWG

YELLOW 20 AWG

RED/ BLUE 20 AWG

RED / WHITE 20 AWG

WHITE 22 AWG

GREEN 22 AWG

TAN 20 AWG

TAN/ BLACK 20 AWG

MOTOR TEMP

OPTIONAL ECONOMY SWITCH (NOTE*7)

YELLOW/ BLACK 20 AWG

FWD/ REV SWITCH (NOTE*8)

R3

MOLEX MINI FIT JR

39-01-2080

BLACK 22 AWG

RED 22 AWG

WHITE 22 AWG

CAN TERMINATION

S3

GREEN 22 AWG

TACHOMETER DRIVER

START BUTTON INPUT

BLACK 20 AWG

BROWN 20 AWG

CLUTCH/ SHIFT SWITCH

N.C. PEDAL INTERLOCK (SEE THROTTLE SCHEMATICS)

ECONOMY MODE

CAN HIGH

WHITE/ BLUE 20 AWG

MULTIPLE

CONDUCTOR

CABLE

OPTIONAL CLUTCH / SWITCH (NOTE *6)

R1

AMP

#776164-1

1

2

3

5

6

7

8

9

11

12

13

14

21

23

25

26

35

28

29

31

32

33

34

1

6

5

8

PRECHARGE

GREY 20AWG

PURPLE 20 AWG

ORANGE / BLACK 20 AWG

R5

DEUTSCH

DTM-06-2S

ORANGE 20 AWG

CAN LOW

GREY 20 AWG

OPTIONAL

CAN BUS

SEE BRAKE

SCHEMATICS

BRAKE SWITCH INPUT

LABEL

“# 14”

WHITE/ BLACK 20 AWG

MALE 3/16” QD

OPTIONAL BRAKE SWITCH INPUT (NOTE *9)

S1

FEMALE

3/16” QD

LABEL

“# 7”

IGNITION KEY

SWITCH

OEM WIRING

LOCK

ACC

ON

START

OEM WIRING

0

12

TACHOMETER

6

Pull up Resistor

(Note *3)

OEM WIRING

12V

Optional Start

Switch (Note*5)

BRAKE LIGHT RELAY

ORANGE 20AWG

SEE BRAKE

SCHEMATICS

1

2

S2

LABEL

“# 26”

FEMALE

1/4” QD

BRAKE POT WIPER

MALE 3/16” QD

LABEL

“# 17”

YELLOW/ RED 20 AWG

FEMALE 3/16” QD

SEE BRAKE

SCHEMATICS

17

POT WIPER

YELLOW/ WHITE 20 AWG

POT HIGH

BLACK/ WHITE 20 AWG

POT LOW

PURPLE/ WHITE 20 AWG

FEMALE 3/16” QD

MALE 3/16” QD

FEMALE 1/4” QD

MALE 1/4” QD

LABEL

“# 15”

LABEL

“# 18”

SEE THROTTLE

SCHEMATICS

15

16

18

A

B

+A1

A2-

COM

NO

4

U

V

W

B +

B -

35

PI

N

CO

NN

EC

TO

R

(SE

E R

1)

A

B

+

-

VISIO

1

1

B

1239 “E” CONTROLLER

ON-ROAD VEHICLE CONVERSION /

PRIMARY DUAL MOTOR SCHEMATICS

NONE

none

4/11/16

A

DRW SIZE

APPLICABLE

SOFTWARE

CAD TYPE

UNIT

DRAWING

TITLE

SCALE

DATE

REVISION

SHEET

HPEVS

OF

SUPPLIER PART

1010‐AUTO1239‐PRI‐VER365.000

HW-1010AUTO1239-HPG

Version 365.000 & Up

NOTES:

(*1)

Use supplied Contactor (GIGAVAC Part # GV200PA-1).

Use only a contactor WITHOUT A PWM AND COIL

SUPPRESSOIN. FAILURE TO DO SO CAN CAUSE

CONTROLLER FAILURE AND WILL VOID THE

WARRANTY.

(*2) Use supplied Pre-Charge Resistor and Relay (Tyco

Electronics Part # T9AP1D52-12).

For Coil connection, connect to small terminals.

(*3) Tachometers that are designed to work off of an ignition

coil may not function in this application. Some Tachometers

may need a pull up resistor of 4.7K Ω to function

(*4) A Battery Management System (BMS) is strongly

recommended if Lithium Ion batteries are used. Possible

source of BMS is Ewert Energy System’s ORION BMS

(www.orionbms.com)

(*5) Start switch is required if

Idle or Creep Torque

parameters are ENABLED

. See Programming Instructions.

A start switch CAN be used without IDLE.

See programming instructions for information

(*6) Install the Optional Clutch/Shift Switch so that is ON

when the clutch pedals is pressed. When clutch pedal is

pressed the regen setting is changed to Shift Neutral

Braking Parameter to prevent the motor from stalling during

gear shifting. In a clutch less system, this allows you to set

the coast down rate of the motor so that the gears align

properly.

See Instructions on SHIFT-NEUTRAL BRAKING

PARAMETERS.

(*7) Allows the use of ECONO Mode Parameters.

See Programming Instructions.

(*8) Forward is CLOCKWISE motor rotation from Encoder

end view. Depending on Transmission configuration, use

either wire to obtain desired rotation. Use FWD & REV

Switch in direct drive applications.

(*9) See Brake Schematics

(*10) Use Pack Fuse rated at 400A for Single controller

applications. For Dual controller use 800A Pack Fuse.

(*11) Only for Dual motor application. Use Controller Fuse

rated at 400A for each controller.

(*12) Gives access to Drive System information. Required to

access Programming and Diagnostic modes.

See Programming Instructions.

PROGRAMMING

PORT

REV

DESCRIPT ION

APPROVED

A

Ini ti al Rel ease

4/ 11/ 2016

REVISIONS

U

MOTOR

MO

TO

R

ENCO

DE

R

H

AR

N

ESS

C

O

N

N

EC

TO

R

W

V

P4

DEUTSCH

DT-04-6P

WHITE/ RED 20 AWG

MENU BUTTON

10

MENU BUTTON (NOTE *12)

FORWARD

WHITE 20 AWG

22

P4

DEUTSCH

DTM-04-4P

P4B

DEUTSCH

DTM-04-2P

1

2

3

4

1

2

Summary of Contents for Curtis 1239 E

Page 8: ...8 GENERIC FULL ELECTRICAL SCHEMATICS 1239 E CONTROLLERS ...

Page 15: ...15 ...

Page 18: ...18 ...

Page 20: ...20 ...

Page 45: ...45 ...