Diagnostic tools and Setup Utilities 80

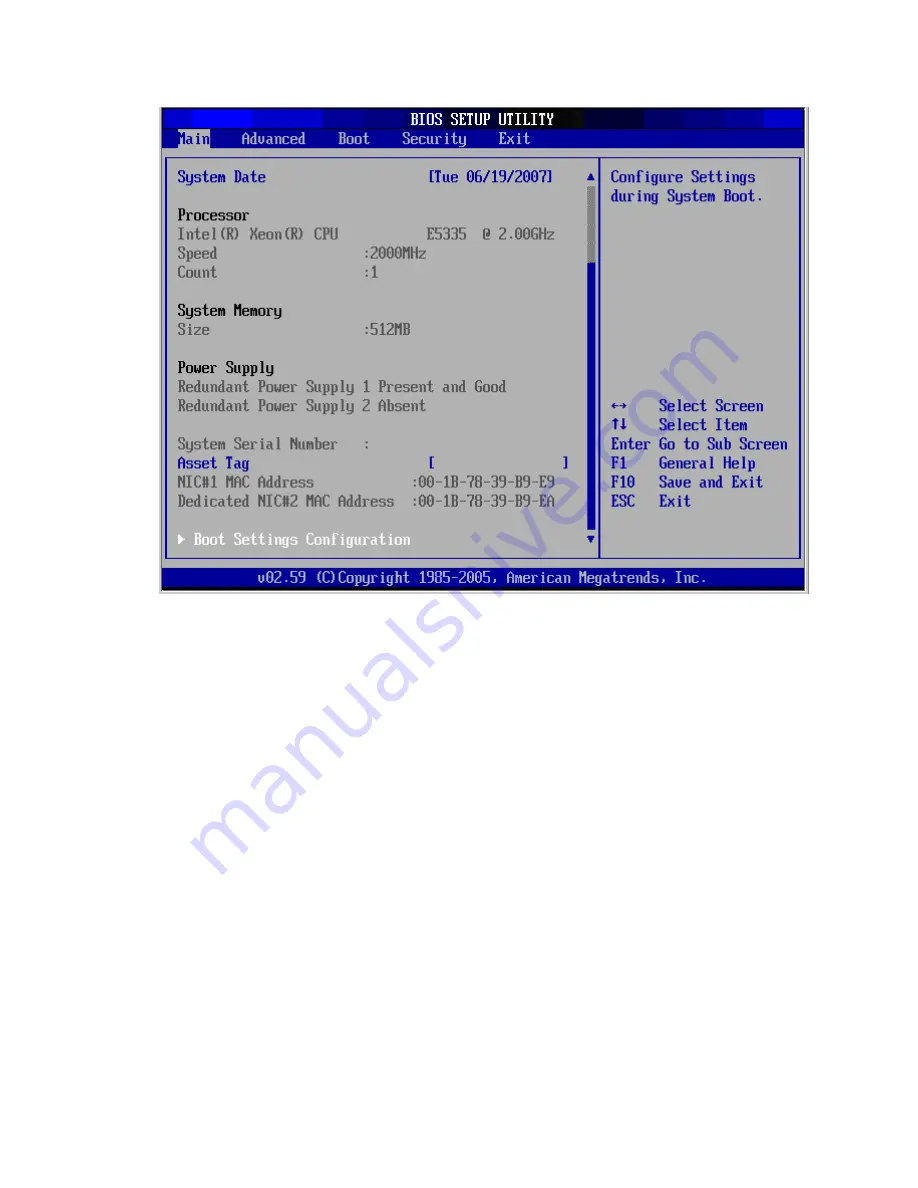

Figure 68

Main menu of the BIOS Setup Utility

Use this menu to set the system time and date, and configure the following items:

•

View BIOS build date and version.

•

View CPU type / CPU speed /CPU physical count information.

•

View System memory size.

•

View Power supply information.

•

View System serial number.

•

View MAC address for the embedded NIC.

•

Set Server Asset Tag.

•

Set system time and date.

•

Set boot features:

○

Enable or disable the BIOS summary display.

○

Turn on or off Bootup Num-Lock.

○

Set restore on AC power loss options, such as last state, power off, and power on.

○

If BIOS displays an error message, set POST F1 Prompt for selections, such as delayed,

enabled, or disabled.

Summary of Contents for ProLiant DL180 G

Page 12: ...Customer self repair 12 ...

Page 13: ...Customer self repair 13 ...

Page 14: ...Customer self repair 14 ...

Page 15: ...Customer self repair 15 ...

Page 19: ...Illustrated parts catalog 19 ...

Page 82: ...Diagnostic tools and Setup Utilities 82 ...

Page 84: ...Diagnostic tools and Setup Utilities 84 Figure 72 Security menu of the BIOS Setup Utility 2 ...