ix

Contents

C4699Ć90000

Introduction

9Ć2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SerialĆNumber Format

9Ć2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Firmware Revision Level

9Ć3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Obtaining Service Notes with Graphics

9Ć4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

From a PC

9Ć4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

From a UNIX Workstation

9Ć4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Problem Reading the Setup Sheet

9Ć5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exchange Assemblies

10Ć2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Parts

10Ć3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part Lists and ExplodedĆView Diagrams

10Ć4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Legs

10Ć4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Top and Back Covers, Electronics, Trailing Cable

10Ć6

. . . . . . . . . . . . . . . . . . . . . .

End Covers

10Ć8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CarriageĆAxis (Left End)

10Ć10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CarriageĆAxis (Right End)

10Ć12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Station, Primer, Spittoon

10Ć14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Entry Path

10Ć16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bail and Overdrive

10Ć18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PinchĆArm Assembly

10Ć22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RollĆFeed Assembly

10Ć24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories

10Ć26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Cables

10Ć29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HewlettĆPackard support services in the United States

11Ć2

. . . . . . . . . . . . . . . . . . . .

HewlettĆPackard support services in Europe

11Ć4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HewlettĆPackard support services in AsiaĆPacific

11Ć8

. . . . . . . . . . . . . . . . . . . . . . . . . .

Summary of Contents for Designjet 230

Page 1: ... ...

Page 3: ... ...

Page 13: ... ...

Page 18: ... ...

Page 19: ... ...

Page 22: ... ...

Page 23: ... ...

Page 25: ... ...

Page 28: ... ...

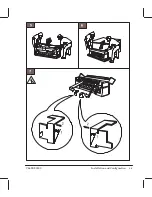

Page 29: ...3Ć7 Installation and Configuration C4699Ć90000 E A0Ćsize plotters only 32Kg 71 lb ...

Page 31: ... 2 1 ...

Page 32: ... ...

Page 33: ... ...

Page 39: ... ...

Page 43: ... ...

Page 59: ... ...

Page 63: ... ...

Page 64: ... Ensure that the cartridge caps are clean the wipers straight and the openings clear ...

Page 66: ... 2 1 ...

Page 69: ... ...

Page 73: ... Clip ...

Page 76: ... 5 5 mm Torx 15 ...

Page 78: ... Torx 15 Leave loose 5 5 mm Tighten slightly Torx 15 Tighten slightly ...

Page 81: ... Torx 20 ...

Page 93: ... Trailing cable under tabs ...

Page 96: ... ...

Page 103: ... the left and right sideĆplates or the lift mechanism will not work ...

Page 109: ... ...

Page 121: ... GO NO GO ...

Page 135: ... ...

Page 137: ... Flashing Can be On or Off Off On ...

Page 168: ... ...

Page 196: ... ...

Page 197: ... ...

Page 202: ... ...

Page 203: ... ...

Page 207: ... ...

Page 209: ...10Ć7 Parts and Diagrams C4699Ć90000 Top and Back Covers Electronics Trailing Cable ...

Page 211: ... ...

Page 213: ... ...

Page 215: ...10Ć13 Parts and Diagrams C4699Ć90000 CarriageĆAxis Right End ...

Page 217: ... ...

Page 219: ... ...

Page 221: ... ...

Page 223: ... ...

Page 225: ... ...

Page 227: ... ...

Page 233: ... ...

Page 242: ......

Page 243: ... ...

Page 249: ... ...