For more information visit:

www.hornby.com

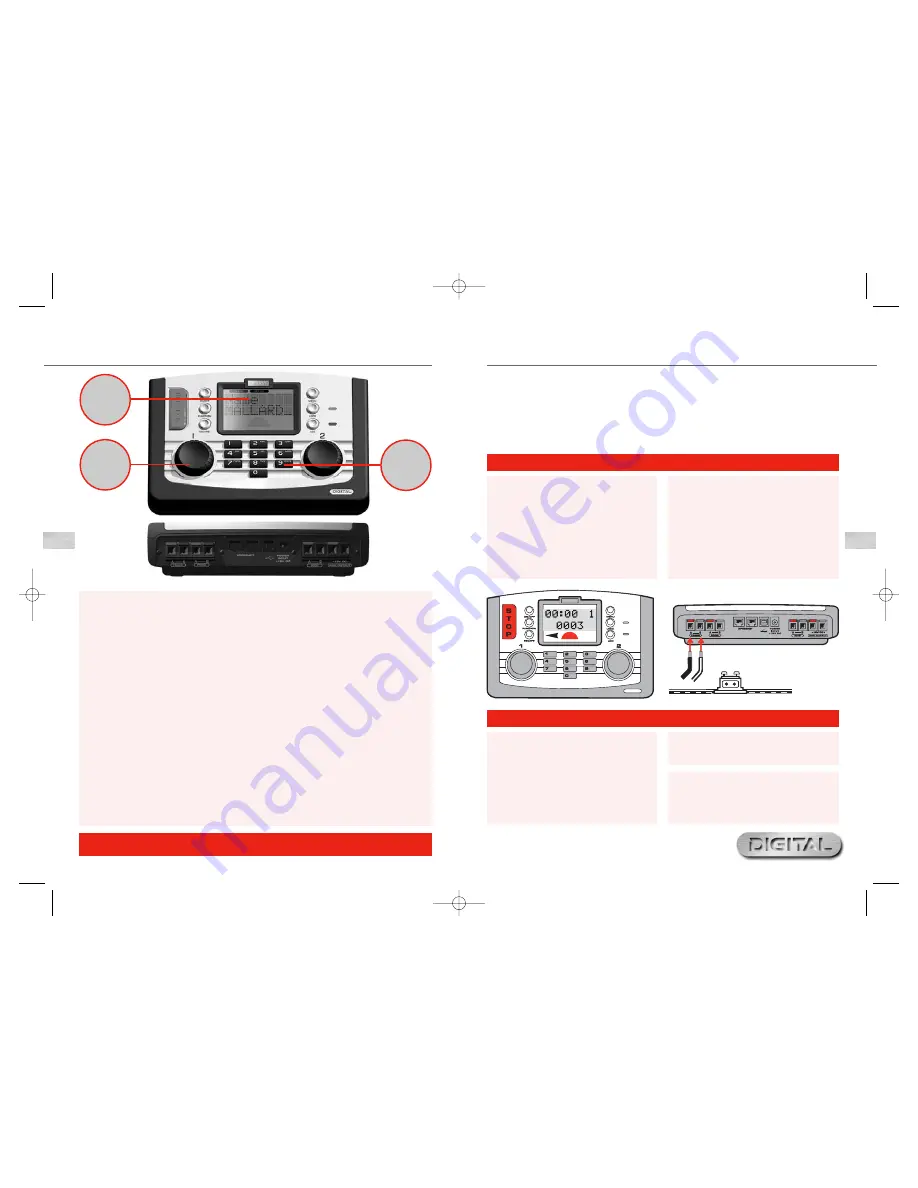

Connecting the Elite Unit to the Track

1.

Locate the terminals at the back of the

Elite

unit

labelled

TRACK

. See Fig 1

2.

Locate the Track to the Controller Link Wire

and insert the black lead into Socket

A

and the

black and white lead into Socket

B

.

(These wires must NOT be inserted into mains

socket outlets.)

3.

If fitted, locate the Hornby Power Input Track

section on the track circuit.

4.

Press down on the left hand button on the Power

Input Track section and insert the black and white

lead of the Link Wire into the socket and release

the button.

5.

Repeat the process inserting the black lead into

the right socket of the Power Input Track.

Connecting the Power Supply

1.

Locate the Power Transformer with integral

cable.

2.

Locate the Power Input socket on the rear of

the unit (

POWER +15V DC

)

3.

Take the Power Supply cable and insert the plug

into the Power Input socket situated at the rear

of the

Elite

unit.

4.

Plug the Power Transformer into the mains socket

and switch on the power.

Keyboard

The 17 button keyboard includes not only buttons 0 – 9

keys which are alpha numeric, but other keys marked

Locomotive

,

Accessory

,

Function

,

On/Off

,

Menu

,

Escape

and of course

Stop

! These multi-function keys

provide the basis for the programming and functioning of

up to 254 locomotives and 255 accessories including points.

The keyboard has the capability of entering into the unit’s

memory the names and numbers of locomotives and

accessories as well as inputting the various functions that

the Hornby Elite offers. Using the Elite’s keypad locomotives

can be addressed from 0 to 9999 and points or solenoid

operated accessories from 1 – 252 if assigned to a Hornby

R8216 Accessory/Points Decoder.

Rotary Control

The Hornby Elite Digital Unit incorporates two rotary

controllers which not only control the assigned locomotives

but also assist in registering each model and accessory to

the Elite.The controls are able to do this by a simple click

and rotate procedure.

This method is also employed to add names and locomotive

numbers to the Elite display so that in place of locomotives

being identified with just their coded number, abbreviated

names and /or running numbers can be used. The pressing

of the Rotary Controls can also determine which knob has

control, the direction of the locomotive’s travel plus point

motor activation.These are just a few of the functions that

are associated with the Rotary Controls, however they do

go some way to illustrate the technical advances that the

Hornby Digital Elite boasts.

LCD Display

The liquid crystal display centred on the Elite has 2 rows

of 8 characters, train direction indicators, a speed indicator,

and a set of 13 numbers which are 0 – 12 which show the

functions that are switched on in respect of locomotives

under direct control.

A clock is also included on the display which can be set to

real time or can be set up to 10X faster. Working with the

Rotary Controls the display will be able to keep the operator

fully up to date with the functionings of the Elite.

Power

The Elite is supplied with a 4 amp transformer. 3 amps is

passed directly to the tracks and 1amp is for the Accessories,

thus the Elite is capable of providing enough power to run

at any one time approximately 10 locomotives depending

on how power efficient the locomotives are.

If the Elite is being connected to an existing layout it must be noted that for Digital Control (DCC) to operate

at its full potential it is important that the locomotives receive a strong and consistent signal from the Elite.

Please ensure the track and connecting fishplates are clean and are firmly connected.

The Hornby Elite unit operates most efficiently when the whole of the layout is “live”. Hornby points are self

isolating therefore it is necessary to fit each point with 2 x

R8232 Hornby DCC Electric Point Clips

.

See page 8 for further information.

Setting Up

4

5

Elite Unit – Fact File

Keyboard

Rotary

Control

LCD

Display

Rotary

Control

LCD

Display

Keyboard

Fig 1

4

Please Note:

There is no On/Off switch on the

Elite

unit.

Always ensure that the power supply is disconnected

from the

Elite

when not in use.

Elite HBook updated 6.3.07_Q6.qxd 13/3/07 13:09 Page 2