If not properly managed running multiple locomotives on one layout can create the potential for accidents and

collisions to occur. To help avoid such incidents the

Hornby Elite Digital Control

unit features an Emergency

Stop button. Pressing this button causes all activity on the layout to cease.

Please Note:

The locomotive that was last under

direct control before the

STOP

button was pressed will function

again if the Controller is rotated.

For more information visit:

www.hornby.com

20

21

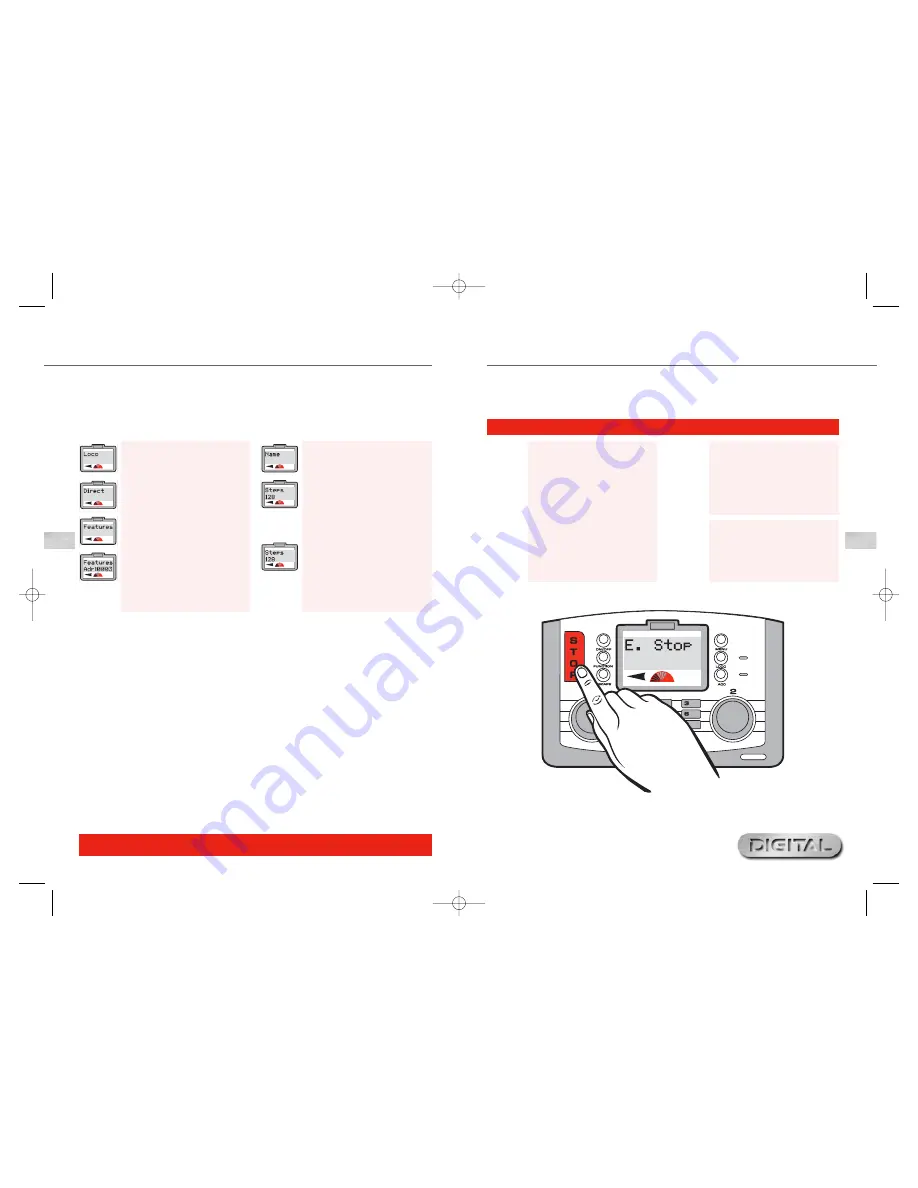

Emergency Stop

Fig 1

Emergency Stop Procedure

1.

Press the

STOP

button located on

the Elite Unit. See Fig 1.

2.

The screen will show “

E. Stop

”

(Emergency Stop).

3.

All activity on the layout will cease.

4.

Allow at least 5 seconds to pass

before restoring the power. Press

STOP

again to restore power to

the layout.

5.

To commence movement each

locomotive will need to be

reselected individually to either

of the controls. This will give the

operator time to reorganise each

locomotive’s movements.

Speed Step Change

1.

Press

Menu

. Screen shows

“

Loco

”.

2.

Press

Control 1

. Screen shows

“

Direct

”.

3.

Rotate

Control 1

until screen shows

“

Features

”. Press

Control 1

.

4.

Screen shows “

Features

Adr:0003

” or the number of the

last locomotive ‘called up’.

5.

Rotate

Control 1

to the locomotive

number required.

6.

Press

Control 1

. Screen shows

“

Name

”.

7.

Rotate

Control 1

until screen

shows “

Steps 128

”. Press

Control 1

.

8.

Rotate

Control 1

until the desired

setting is displayed.

9.

Press

Control 1

to confirm.

Screen shows the steps selected.

10.

Press

Menu

to return to the main

screen.

There may be occasions when locomotives fitted with older generation decoders may be required to be controlled

by the

Elite

. Some of these locomotives may require to be “tuned” to the Elite. NB: There are basically three

main levels of speed steps, 14, 28 and 128. The greater the number of speed steps the smoother the acceleration.

All Hornby decoders are factory set at 128 steps. Locomotive 1 will be used in this example.To alter the Speed

Steps place the locomotive on the Programming Track and follow the instructions below.

Elite HBook updated 6.3.07_Q6.qxd 13/3/07 13:09 Page 18