Programming and Operating Concepts

Video Recorder – User Manual

66

From Figure 3-18, the instrument’s AI1 function block will essentially process the 4 to 20 mA transmitter

signal to generate a pH measurement. This measurement will be “AI1 OV” which, in turn, will be applied

to LP1’s process variable input, “PV.” Before the 4 to 20 mA signal is applied to AI1, it will be converted

to a 1 to 5 VDC signal with a 250

Ω

shunt resistor. AI1 will be configured to generate a pH measurement

in a range from 0 (RANGE LOW = 0) to 14 (RANGE HIGH = 14) in response to a voltage input between

1 (CKT LOW = 1) and 5 (CKT HIGH = 5) VDC. The PID algorithm of the control loop function block will

adjust the value assumed by LP1 OV between 0 and 100%. This 0 to 100% signal will be applied to

AO1, which will be configured as a DAT type analog output. The internal parameter of “IMPULSE TIME”

in AO1 is the DAT analog output’s cycle time or period. With a specified impulse time of 150 seconds

(an arbitrarily picked value), the DAT output will be ON for 75 seconds and OFF for 75 seconds when the

input from LP1 is set to 50%. The ON and OFF times will be determined completely by the % output

levels called for by LP1. Finally, to externalize the ON and OFF output states of AO1 to the outside

world, the DO1 output relay, represented by the DO1 function block, will be programmed for AO1’s

exclusive use. Hence, as AO1 switches between ON and OFF states in response to LP1 OV’s % output

levels, so too will the DO1 output relay to generate the pulses required to drive the caustic reagent

pump.

Split Output or Duplex Control

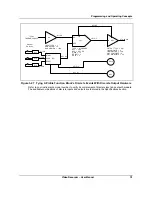

Split output or duplex control loops are typically used in heat/cool applications. Temperature is

controlled through simultaneous use of both heating and cooling elements. If the instrument was to

support a heat/cool control configuration, an example of the control scheme that might be dealt with is

illustrated in Figure 3-19.

VALVE

ACTUATOR

INSTRUMENT

PV 85

SP 95

OUT 73.5%

HOT

WATER

HOT WATER

VALVE

VALVE

ACTUATOR

4 TO 20 mA

(CAT)

COLD

WATER

COLD WATER

VALVE

4 TO 20 mA

(CAT)

WATER TANK

100

Ω

PLATINUM

RTD

Figure 3-19 Temperature Control Of Water Using Split Output Or Duplex Control

The instrument must be set up to produce two 4 to 20 mA control signals. By applying them to current-

controlled valve actuators coupled to hot and cold water valves, these signals will regulate the amount of

hot and cold water introduced to the vessel to maintain the water temperature at whatever set point will

be programmed. The temperature of the water will be measured by means of a three-wire 100

Ω

Platinum RTD. This process may be likened to manipulating hot and cold faucets regulate water

temperature.

Summary of Contents for VRX180

Page 1: ...Issue 3 03 03 US1I 6228 Video Recorder VRX180 User Manual ...

Page 2: ...Issue 3 03 03 US1I 6228 ...

Page 6: ...iv Video Recorder User Manual ...

Page 48: ...Installation Video Recorder User Manual 34 ...

Page 222: ...Setpoint Profiler Video Recorder User Manual 208 ...

Page 234: ...Online Operations Using Primary Displays Video Recorder User Manual 220 ...

Page 278: ...Appendix A Video Recorder User Manual 264 ...