Date of Issue: April 2008

4-5

WDP30X

c. INSPECTION

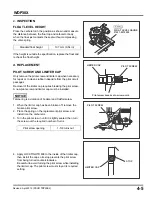

FLOAT LEVEL HEIGHT

Place the carburetor in the position as shown and measure

the distance between the float top and carburetor body

when the float just contacts the seat without compressing

the valve spring.

If the height is outside the specification, replace the float and

recheck the float height.

d. REPLACEMENT

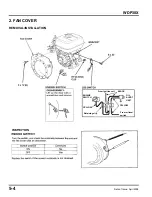

PILOT SCREW AND LIMITER CAP

Only remove the pilot screw and limiter cap when necessary

for repair or to clean stubborn deposits from the pilot circuit

passages.

Removal of the limiter cap requires breaking the pilot screw.

A new pilot screw and limiter cap must be installed.

NOTICE

Tampering is a violation of Federal and California law.

1. When the limiter cap has been broken off, remove the

broken pilot screw.

2. Place the spring on the replacement pilot screw, and

install it on the carburetor.

3. Turn the pilot screw in until it is lightly seated, then turn

the screw out the required number of turns.

4. Apply LOCKTIGHT® 638 to the inside of the limiter cap,

then install the cap so its stop prevents the pilot screw

from being turned counterclockwise.

Be careful to avoid turning the pilot screw while installing

the limiter cap. The pilot screw must stay at its required

setting.

Standard float height

13.7 mm (0.54 in)

Pilot screw opening

1-5/8 turns out

Pilot screw breaks at narrow point.

LIMITER CAP

PILOT SCREW

FLOAT LEVEL GAUGE

07401-0010000

PILOT SCREW

STOP

LIMITER CAP

Revised: April 2012 (PSV61TDP00E2)

Summary of Contents for WDP30X

Page 3: ...ii Revised April 2012 PSV61TDP00E2 WDP30X...

Page 9: ...1 6 Date of Issue April 2008 WDP30X...

Page 19: ...2 10 Date of Issue April 2008 WDP30X...

Page 43: ...6 2 Date of Issue April 2008 WDP30X...

Page 47: ...7 4 Date of Issue April 2008 WDP30X...

Page 55: ...8 8 Date of Issue April 2008 WDP30X...