19

C

ha

ss

is

- 1

0

2012 Trip

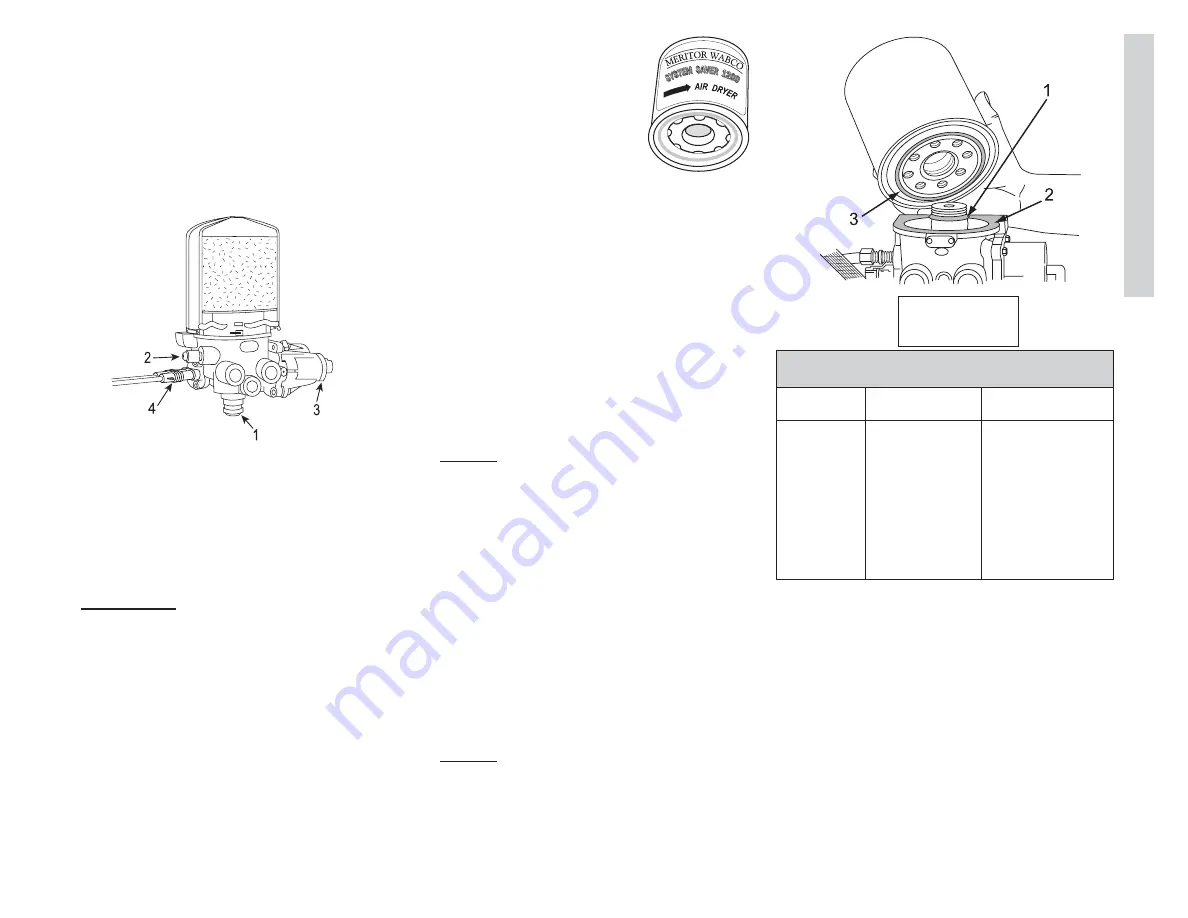

3. Regeneration Valve:

Controls

regeneration of the desiccant by

allowing air from the supply and

secondary tanks to bypass the outlet

check valve.

4. Heater Power Connection:

Provides

12 Volt DC power to the heating

element.

In extreme cold, verify that the air dryer

heater is in good working order. The 100-watt

heater in the air dryer is controlled by ignition

power. The heater turns on below 45° F and

off when the air dryer temperature is above

86° F.

WARNING:

Remove all pressure from the air

system before disconnecting any

component, including the desiccant

cartridge. Pressurized air can cause

serious personal injury.

Desiccant Cartridge

Warm, humid air from the

compressor condenses into

either water or water vapor.

A desiccant-type air dryer

protects the air brake system

by drying moisture-laden air

before it passes through the air reservoirs and

into the brake system. The replacement kit

contains one cartridge and one O-ring.

To Replace the Cartridge:

Loosen and remove the old cartridge.

Use a strap wrench, if necessary.

Remove and discard the O-ring from

the dryer base.

Inspect and clean the seal seat. Repair

any minor damage.

NOTE:

If the seats are damaged that a tight

seal cannot be maintained, replace the

air dryer.

Install a new O-ring.

Lubricate the O-ring on the stem with a

thin layer of grease.

Lubricate the cartridge seal with a thin

layer of grease.

Thread the replacement cartridge onto

the base until the seal touches the base.

Tighten the cartridge One additional

turn. Do not

overtighten.

NOTE:

If an excess amount of water is present

when performing the monthly air

tank drain service, the filter for the air

dryer may need to be changed.

Desiccant-Type Air Dryer

Warm, humid air from the compressor

condenses into either water or water vapor

before entering the air dryer.

A desiccant-type air dryer protects the

motorhome air brake system by drying

moisture-laden air before it passes through

the air reservoirs and into the brake system.

Water collects in the base of the dryer

when warm air condenses the water before

it enters the dryer, or inside of the dryer

before the water reaches the desiccant.

070164b

070165

RepLacement RequiRements

components When to replace? Why?

Desiccant

Cartridge

•

Every two to

three years.

•

When

compressor is

replaced.

•

Water in supply

tank.

•

Preventive

maintenance.

•

Contaminated

cartridge.

•

Saturated or

contaminated

cartridge, high

duty cycle (wrong

application of air

dryer).

080223

1. O-ring

2. Seal Seat

3. Cartridge Seal

Summary of Contents for Trip 2012

Page 1: ...2 0 1 2 B YHOL I D A YR A MB L E R O w n e r s Ma n u a l...

Page 13: ...Notes...

Page 45: ...40 Driv ing Safety 2 2012 Trip Weight Record Sheet...

Page 51: ...46 Driv ing Safety 2 2012 Trip Notes...

Page 138: ...133 W ater Sy stems 6 2012 Trip Water System Diagram 040487va...

Page 139: ...134 Wat er Sy stems 6 2012 Trip Notes...

Page 151: ...146 Pro p ane Sy tems 7 2012 Trip Notes...

Page 173: ...168 Ho us e Electr ical 8 2012 Trip Notes...

Page 190: ...185 Chassis Electrical 9 2012 Trip Engine No Start Flow Chart...

Page 191: ...186 Ch as s is Electr ical 9 2012 Trip Notes...

Page 237: ...232 Ch assis 10 2012 Trip Notes...