41

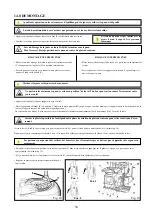

• Check that the tyre is deflated. If not, deflate it.

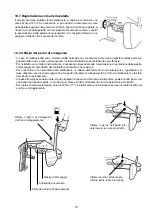

• Close the clamps (G) of turntable (Y) completely and position the turntable in a way that one of the concave sides is paral

lel to the rubber support surface (S) of the bead-breaker.

• Position the wheel against the rubber stops on the right side of the tyre changer (S).

• Position the bead breaker blade (R) against the tyre bead at a distance of about 1 cm from the rim (fig.15). Pay attention to

the blade, which must operate correctly onto the tyre and not onto the rim.

• Press down the pedal (U) to activate the bead breaker and release it when the blade has reached the end of its travel or in

any case when the bead is broken.

• Rotate the tyre slightly and repeat the operation around the entire circumference of the rim and from both sides until the

bead is completely detached from the rim.

Bead breaking must be done with the utmost care and attention. When the bead breaker pedal is ope-

rated the bead breaker arm moves quickly and powerfully. Anything within its range of action can be

in danger of being crushed.

Bead breaking with the clamps in open position can be extremly dangerous for operator's hands.

During bead breaking operations NEVER touch the side of the tyre.

R

Fig. 15

Fig. 14

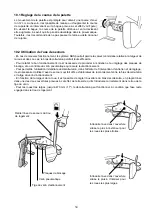

11.0 BEAD BREAKER ARM ADJUSTING OPERATIONS

11.1 SBS (Smart Blade System)

- Using a suitable tool, remove all the counterweights from the rim, being

extra careful not to damage the rim itself

- Before starting any work, ensure there is no pressure sensor. If any, we

suggest checking its state of efficiency using a suitable tool.

- Position the wheel on the roller unit as shown in the figure on the right.

- Keeping push button W pressed, bring the blade up to the edge of the rim

without touching it. Release the button to memorise and block the blade in

the stroke start position.

- Press and release pedal U repeatedly by turning with both hands free the

wheel on top of the roller unit until the outside has been completely beaded

and then repeat on the inside until the tyre has been completely beaded-

Always DEFLATE the tyre completely before doing any work on it, removing the needle valve

The tyre changer has an exclusive and patented blade bead breaking system that makes work quicker reducing

the hard work for the operator and ensuring no damage to the tyre in compliance with the WDK standards

W

Summary of Contents for Megamount 703 XL

Page 80: ...80 24 DATI TECNICI TECHNICAL DATA DONNEES TECHNIQUES TECHNISCHE DATEN ...

Page 83: ...83 110V 1PH ...

Page 85: ......