●

Standard Communication Functions 6-7

Assume that the printer is ready for printing.

1

6.3.3 Print Condition Transmission

●

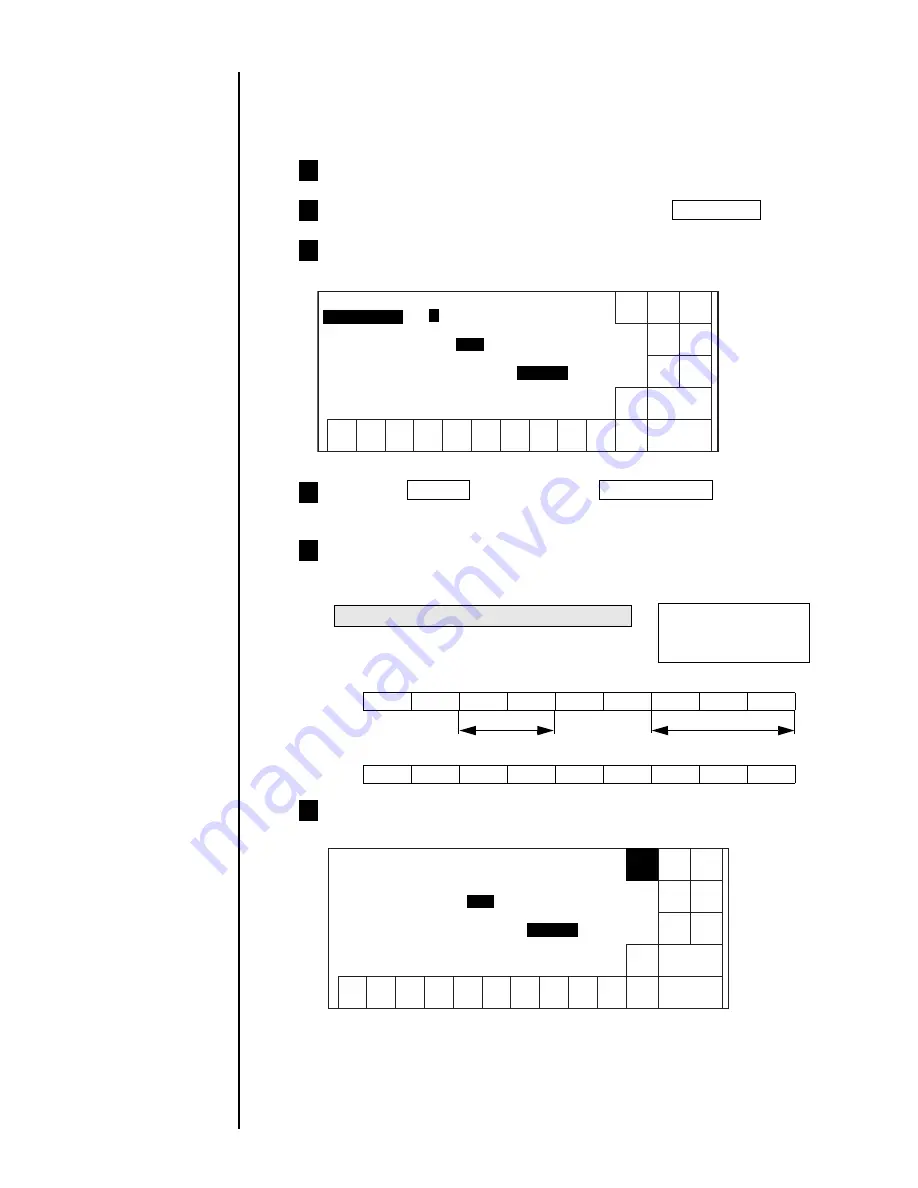

The procedure for changing the character height from "99" to "90" and change

the character width from "050" to "000."is shown in the example below.

From the "Print description" screen, press Print spec .

2

You can see a character height setting of 99 and character

width of "050" entered.

3

Transmit character height data and character width data from

the external device to the IJ printer.

5

Shows text data between STX and ETX

Transmission data

ESC Header

9

0

ESC Header

0

0

0

Transmission code

1BH

30H

39H

30H

1BH

31H

30H

30H

30H

Character width

Character height

Number of character

height digits

In the case of "2 digits"

Shut

down

Manual

Back

←

→

Prev.

dis-

paly

Next

dis-

paly

Decre-

ment

Incre-

ment

1

2

3

4

5

6

7

8

9

Print specifications

Status: Ready

0

[ 9 ] (0-99)

Character width

[ 0 5 0 ] (0-199)

Character orientation [ 0 ] (0: 1: ABC 2: 3: )

(Arrow: Printing direction)

→

←

←

→

Printing method

2 (1:single scan 2: )

9

Character height

Interlaced

ABC

The character height setting then changes to "90".

The character width setting then changes to "000."

6

Shut

down

Manual

Back

←

→

Prev.

dis-

paly

Next

dis-

paly

Decre-

ment

Incre-

ment

1

2

3

4

5

6

7

8

9

Print specifications

Status: Ready

0

Character height

[ 9 0 ] (0-99)

Character width

[ 0 0 0 ] (0-199)

Character orientation [ 0 ] (0: 1: ABC 2: 3: )

(Arrow: Printing direction)

→

←

←

→

Printing method

2 (1:single scan 2: )

Interlaced

ABC

Show

cursor

Press the Manual key then press Online/Offline key.

The status then changes from "off-line (Com=0)" to "on-line (Com=1)".

4

Com=1

ABC

ABC

ABC

ABC

Summary of Contents for PH

Page 288: ...2 K5253 1 ...