2

3. Operation

4. Maintenance, inspection, and parts replacement

5. Others

- While power is supplied to the inverter, do not touch any terminal or internal part of the inverter, check signals, or connect or disconnect any wire or

connector. Otherwise, you run the risk of electric shock or fire.

- Be sure to close the top cover before turning on the inverter power. Do not open the top while power is being supplied to the inverter or voltage

remains inside. Otherwise, you run the risk of electric shock.

- Do not operate switches with wet hands. Otherwise, you run the risk of electric shock.

- While power is supplied to the inverter, do not touch the terminal of the inverter, even if it has stopped. Otherwise, you run the risk of injury or fire.

- If the retry mode has been selected, the inverter will restart suddenly after a break in the tripping status. Stay away from the machine controlled by

the inverter when the inverter is under such circumstances. (Design the machine so that human safety can be ensured, even when the inverter

restarts suddenly.) Otherwise, you run the risk of injury.

- Do not select the retry mode for controlling an elevating or traveling device because output free-running status occurs in retry mode. Otherwise,

you run the risk of injury or damage to the machine controlled by the inverter.

- If an operation command has been input to the inverter before a short-term power failure, the inverter may restart operation after the power

recovery. If such a restart may put persons in danger, design a control circuit that disables the inverter from restarting after power recovery.

Otherwise, you run the risk of injury.

- Prepare the additional emergency stop switch in addition to the stop key of the integrated operator and/or the optional operator. Otherwise, there

is a danger of injury.

- If an operation command has been input to the inverter before the inverter enters alarm status, the inverter will restart suddenly when the alarm

status is reset. Before resetting the alarm status, make sure that no operation command has been input.

- While power is supplied to the inverter, do not touch any internal part of the inverter or insert a bar in it. Otherwise, you run the risk of electric

shock or fire.

- Run/Stop/Reset is integrated in one button, before you press the button, please make sure that the machine(facility) can be operated.

Otherwise, you run the risk of injury or damage to the machine controlled by the inverter.

- Do not touch the heat sink, which heats up during the inverter operation. Otherwise, you run the risk of burn injury.

- The inverter allows you to easily control the speed of motor or machine operations. Before operating the inverter, confirm the capacity and ratings of

the motor or machine controlled by the inverter. Otherwise, you run the risk of injury.

- Install an external brake system if needed. Otherwise, you run the risk of injury.

- When using the inverter to operate a standard motor at a frequency of over 60 Hz, check the allowable motor speeds with the manufacturers of the

motor and the machine to be driven and obtain their consent before starting inverter operation. Otherwise, you run the risk of damage to the motor

and machine.

- During inverter operation, check the motor for the direction of rotation, abnormal sound, and vibrations. Otherwise, you run the risk of damage to the

machine driven by the motor.

- Regardless Run command setting(A002/A202) if the key is pressed, the inverter starts running. Therefore, if you selected Run command such as

operator or terminal, please handle the key after you made sure that the machine/facility can be operated safely.

- Before inspecting the inverter, be sure to turn off the power supply and wait for 10 minutes or more. Otherwise, you run the risk of electric shock.

(Before inspection, confirm that the Charge lamp on the inverter is off.)

In case the power indication of the operator does not turn ON after power-up, inverter may be damaged. In that case, the inspection must be done

after waiting two hours or more of the power OFF. Otherwise there is a danger of electric shock and/or injury.

- Commit only a designated person to maintenance, inspection, and the replacement of parts.

(Be sure to remove wristwatches and metal accessories, e.g., bracelets, before maintenance and inspection work and to use insulated tools for the

work.) Otherwise, you run the risk of electric shock and injury.

- Never modify the inverter. Otherwise, you run the risk of electric shock and injury.

Do not discard the inverter with household waste. Contact an industrial waste management company in your area who can treat industrial waste

without polluting the environment.

- Do not discard the inverter with household waste. Contact an industrial waste management company in your area who can treat industrial waste

without polluting the environment.

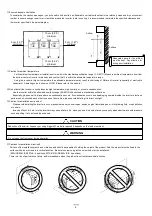

CAUTION

WARNING

WARNING

WARNING

CAUTION