11

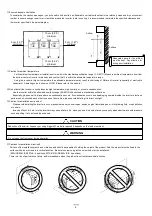

④

Inverter ground terminal (G )

・

Be sure to ground the inverter and motor to prevent electric shock.

・

According to the Electric Apparatus Engineering Regulations, connect 200 V class models to grounding electrodes constructed in compliance

with type-D grounding (conventional type-III grounding with ground resistance of 100

Ω

or less) or the 400 V class models to grounding electrodes

constructed in compliance with type-C grounding (conventional special type-III grounding with ground resistance of 10

Ω

or less).

・

Use a grounding cable thicker than the specified applicable cable, and make the ground wiring as short as possible.

・

When grounding multiple inverters, avoid a multi-drop connection of the grounding route and formation of a ground loop, otherwise the inverter

may malfunction.

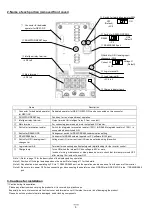

(2) Layout of main circuit terminals

The figures below show the terminal layout on the main circuit terminal block of the inverter.

The main circuit terminal block opens a faceplate and wires it.

Single-phase 200V 0.2 to 0.4kW

Three-phase 200V 0.2 to 0.75kW

(4)Wiring and Accesories

The table below lists the specifications of cables, crimp terminals, and terminal screw tightening torques for reference.

Input

Voltage

Motor

output

(kW)

Applicable

inverter

model

NES1-

Wiring

Accessories

Note1)

Gauge of power line

cable (mm

2

)

Note3)

Note4)

Size of terminal

screw

Terminal width

(mm)

Tightening

torque

(N-m)

Earth-leakage

breaker (ELB)

Note2)Note5)

Magnetic

contactor

(MC)

Note2)

Fuse

(UL-rated,

class J,600V)

Note6)

1-phase

200V

0.2

002SB

AWG14 (2.0)

M3.5 (7.6)

1.0

EX30 (5A)

H10C

10A

0.4

004SB

AWG14 (2.0)

M3.5 (7.6)

1.0

EX30 (10A)

H10C

10A

0.75

007SB

AWG14 (2.0)

M4 (10)

1.4

EX30 (15A)

H10C

15A

1.5

015SB

AWG10 (5.5)

M4 (10)

1.4

EX30 (20A)

H20

20A

2.2

022SB

AWG10 (5.5)

M4 (10)

1.4

EX30 (20A)

H20

30A

3-phase

200V

0.2

002LB

AWG16 (1.25)

M3.5 (7.6)

1.0

EX30 (5A)

H10C

10A

0.4

004LB

AWG16 (1.25)

M3.5 (7.6)

1.0

EX30 (10A)

H10C

10A

0.75

007LB

AWG16 (1.25)

M3.5 (7.6)

1.0

EX30 (10A)

H10C

15A

1.5

015LB

AWG14 (2.0)

M4 (10)

1.4

EX30 (15A)

H10C

15A

2.2

022LB

AWG14 (2.0)

M4 (10)

1.4

EX30 (20A)

H20

20A

Note 1)The peripheral equipment described here is applicable when the inverter connects a standard Hitachi 3-phase, 4-pole squirrel-cage motor.

Note 2)Select breakers that have proper capacity. (Use breakers that comply with inverters.)

Select above proper ELB capacity following above table

for the 1pc inverter. Only 1 inverter must be supplied by the above proper ELB.

Note 3)If the power line exceeds 20m, cable that is thicker than the specified applicable cable must be used for the power line.

Note 4)Use copper electric wire (HIV cable) of which the maximum allowable temperature of the insulation is 75°C.

Note 5)Use earth-leakage breakers (ELB) to ensure safety.

Note 6)To comply UL, use either ELB/or FUSE which is specified by UL for the Power supply for the inverter.

Note 7)The ground or earthed line should be a larger gauge than electric supply wire diameter used in the power line.

Three-phase type

Single-phase

type

Three-phase

type

From source

To motor

L1

N

P/+

PD/+1

W/T3

V/T2

U/T1

R/L1

T/L3

P/+

PD/+1

W/T3

V/T2

U/T1

S/L2

Single-phase type

L1

N

PD/+1

P/+

U/T1

W/T3

V/T2

R/L1

T/L3

S/L2

W/T3

V/T2

U/T1

PD/+1

P/+

From source

To motor

Single-phase 200V 0.75 to 2.2kW

Three-phase 200V 1.5, 2.2kW

Charge lump

Charge lump

Inverter

Inverter

Inverter

Grounding bolt

prepared by user

Inverter

Inverter

Inverter