10

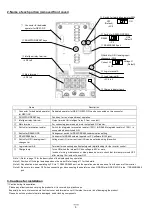

4.3 Mains wiring

(1) Cautions on wiring

Be sure to confirm that the charge lamp is turned OFF before the wiring work.

Once it is powered up, there will be a remaining voltage at the DC bus capacitor for a certain period regardless the motor operation.

Wiring work must be done 10 minutes after the power off, and after confirming the safety of personnel.

In case the power indication of the operator does not turn ON after power-up, inverter may be damaged. In that case, the inspection must be done

after waiting two hours or more of the power OFF. Otherwise there is a danger of electric shock and/or injury.

①

Mains input terminals (R/L1,S,T/N)

・

Use earth leakage breaker (ELB) for protection between power supply and input terminals (R/L1,S,T/N).

・

The ELB is recommended to have bigger capability for the high frequency sensitivity, so to avoid malfunction.

Distance between

inverter and motor

Cutoff current

of ELB

100m or less

30mA

300m or less

100mA

800m or less

200mA

・

There is a possibility that the malfunction or failure of the customer’s system when the protection circuit of the inverter is activated. Please use

magnetic contactor to shutoff the inverter power supply.

・

Do not turn power ON and OFF by the magnet contactor at the primary side or secondary side of the inverter to start and stop the motor. Use

operation command (FW, RV) from the control input terminal in case of using external signal.

・

Do not use the 3-ph input type with single phase input (phase loss). Otherwise there is a risk of inverter failure. Single phase input to the 3 phase

type inverter will result in a undervoltage, overcurrent, or will result in a damage of the inverter. [DC bus capacitor will be charged even under

phase loss and it is dangerous. Refer to “(1) Cautions for wiring” for the wiring.]

・

There is a risk of breakdown of the internal converter module, and/or shortening drastically the lifetime of DC bus capacitors due to an increase

of the ripple current. Especially, if high reliability is required on the system, use AC reactor between power supply and inverter. And if severe

weather,such as thunderstorms is expected, use appropriate lightning protection equipment.

- Unbalance at the input voltage (3% or more)

- Impedance of the power supply is 10 times or more, and 500kVA or more

- Rapid change is voltage is expected

(Example)

- 2 or more inverters are connected at the same net with short cable.

- Inverter is connected in parallel with the thyristor equipment with short cable.

- Phase advancing capacitor is switching on a same net

・

Frequency of the power ON/OFF must be once/3 minutes or longer interval. There is a danger of inverter failure.

・

An inverter run by a private power generator may overheat the generator or suffer from a deformed output voltage waveform of the

generator. Generally, the generator capacity should be five times that of the inverter (kVA) in a PWM control system or six times greater

in a PAM control system.

・

In the case of important equipment, to shorten the non-operational time of inverter failure, please provide a backup circuit by commercial power

supply or spare inverter.

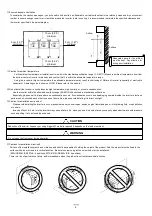

・

In case of commercial power source switching functionality,mechanical interlock the MC1 & MC2 contacts with each others is required.Otherwise

you may damage the inverter and the danger of injury and/or fire.Please refer to following diagram.

②

Inverter output terminals (U, V, and W)

・

Use larger gauge cable leads than the specified applicable cable for the wiring of output terminals to prevent the output voltage drop between the

inverter and motor. Especially at low frequency output, a voltage drop due to cable resistance will cause the motor torque to decrease.

・

Do not connect a phase-advanced capacitor or surge absorber on the output side of the inverter. If connected, the inverter may trip or the

phase-advanced capacitor or surge absorber may be damaged.

・

If the cable length between the inverter and motor exceeds 20 m (especially in the case of 400 V class models), the stray capacitance and

inductance of the cable may cause a surge voltage at motor terminals, resulting in a motor burnout. A special filter to suppress the surge voltage

is available. If you need this filter, contact your supplier or local Hitachi Distributor.

・

When connecting multiple motors to the inverter, connect a thermal relay to the inverter output circuit for each motor.

・

The RC rating of the thermal relay must be 1.1 times as high as the rated current of the motor. The thermal relay may go off too early, depending

on the cable length. If this occurs, connect an AC reactor to the output of the inverter.

③

DC reactor connection terminals (PD and P)

・

Use these terminals to connect the optional DC power factor reactor (DCL).

As the factory setting, terminals P and PD are connected by a jumper. Remove this to connect the DCL.

・

The cable length between the inverter and DCL must be 5 m or less.

Remove the jumper only when connecting the DCL.

If the jumper is removed and the DCL is not connected, power is not supplied to the main circuit of the inverter, and the

inverter will not operate.

[Rough indication of earth leakage current] 30mA/km : use CV cable with metallic tube. Leakage

current will be approximately 8 times more when using H-IV cable.

Therefore, it is recommended to use one class bigger capability of the ELB. Previously mentioned

“leakage current” is based on the RMS value of fundamental wave, excluding harmonic current.

Power

source

R/L1

U

S

Inveter V

T/N

W

Motor

ELB

MC0

MC1

MC2