18

4. HOW TO SERVICE THE AIR COMPRESSOR

4.1 Replacement of Air Intake Filter (Bi-Annually)

■

Filter Specifications

Effective filtration area: 40.8 ft² (3.79

m

2

)

Filtration efficiency: 98% or higher (full life)

12.7mm

254mm

φ

241.2mm

(0.50inch)

(10.0inch)

(

φ

9.50inch)

Before servicing the air compressor, stop it, disconnect the power (turn off the earth leakage (ground) circuit

breaker) and verify that the compressor’s internal pressure has dropped to atmospheric pressure.

The maintenance intervals shown refer to the standard Maintenance Schedule (A).

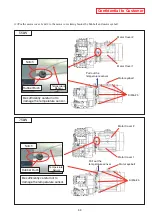

A pressure sensor is provided on the suction throttle

valve to detect the pressure differential across the air

intake filter. When the sensor detects a pressure

differential as large as 0.72 psi (4.98 kPa) during

operation, AIR FILTER appears on the LCD display

with E0.21 on digital monitor. If this occurs, clean or

replace the air intake filter in accordance with

Maintenance Schedule (A) or (B). The procedure for

cleaning the air intake filter is as follows.

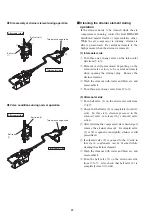

①

Stop the air compressor, disconnect the power and

verify no internal pressure.

②

Remove the front door (1).

③

Remove the cover and wipe away the dirt inside of

the duct before removing the air intake filter.

④

Loosen the wing nut and remove the air intake filter.

Make sure the contamination and/or dust doesn’t

enter the airend side.

⑤

Tap the air intake filter to remove large particles.

Then blow air to clean the surface of filter.

⑥

In the case of oily or carbon dust, dip the element

into neutral detergent and water solution for about 30

minutes. Rinse the element several times with clean

water (water pressure is less than 39 psi (0.27MPa))

and air-dr y it. Confirm the element is dried

completely.

⑦

Reinstall and tighten the wing nut.

Differential pressure sensor

Cover

Air Intake filter

Wing nut

Duct

CAUTION

If the air intake filter is clogged with dust/dirt particles; Differential pressure (resistance of flow) across

the air intake filter increases, which results in decreased air intake to the airend and a rise in discharge

air temperature. To avoid a problem, service the air intake filter regularly. If the compressor room

environment is dusty or dirty, service the air intake filter more frequently than instructed on the

Maintenance Schedule.