28

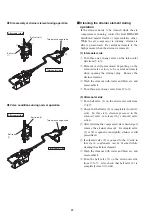

Load-side bearing

Grease port

Anti-Load-Side bearing

Grease port

Grease pan

Grease pan

CAUTION

Be cautious of replenishing grease more than the spcified amont. It may cause leaking of grease and/or

malfunction of the protective device due to overheat of the bearing. Grease at once during start-up

commissioning. Periodically replace the main motor bearing in accordance with

“

3. Maintenance”

Maintenance Schedule A Maintenance Schedule B in pages 13 to 16

[Fixed speed type]

Grease pan

Load-side bearing

Grease port

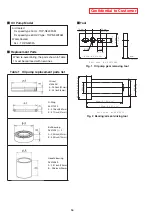

●

Example of grease gun

Lever-type grease gun CH-400 Micro-Hose (pin type

SPK-1C) by Yamada Corporation

Grease filling amount

Operation condition

Filling

frequency

Filling amount

Fixed-speed Variable-speed

For 8,000 hours or less

operating hours per year

Every 3

months

Fill 2.3 oz

(65 g) each

on the load

and opposite

sides.

Fill 2.6 oz

(75 g) on the

load side.

For 4,000 hours or less

operating hours per year

Every 6

months

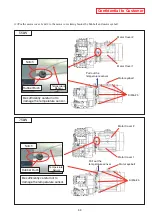

①

Open the front door. Inject a specified amount of

grease through the grease inlet using a grease gun.

②

If used grease is discharged in the grease pan under

the grease inlet, clean the pan as necessary.

③

Close the front door.

The bearing on the opposite side is shield type; filling

of grease is not necessary on the opposite side.

●

Contact the local HITACHI distributor/master dealer or

representative office for the grease detail.

●

Greasing must be done while the main motor

operating.

●

Cleaning of grease pan must be done while the air

compressor stops.

IMPORTANT

The main motor bearings must be greased as following

table.

Grease following amount of RMS grease (Ref. No. 455)

(Raremax Super by Kodo Yushi) .

4.10 Main Motor Greasing