52

Confidential to Customer

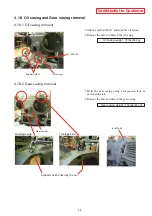

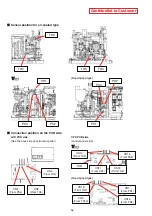

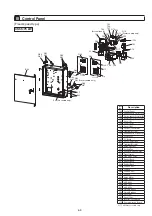

4.21.1 Removing the Air End

Remove the air end.

(

see p. 43

“

4.17 Oil Pump motor and Airend

removal”

4.17.2 Airend removal

)

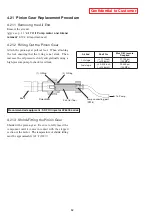

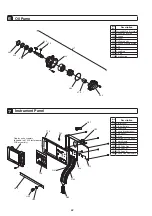

4.21.2 Pulling Out the Pinion Gear

Attach the pinion gear pull-out tool. When attaching

the tool, ensuring that the O-ring is not stuck. Then

increase the oil pressure slowly and gradually using a

high-pressure pump to check for oil leak.

4.21 Pinion Gear Replacement Procedure

Air End

Shaft Dia.

Max Oil Pressure

Required

1st-stage

φ

1.17 inch

( φ

29.8mm)

21750 psi

(150MPa)

2nd-stage

φ

0.976 inch

( φ

24.8mm)

20300 psi

(140MPa)

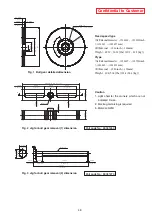

(1) O-Ring

(2) O-Ring

Shaft

Pinion Gear

Pull-Out Tool

To Pump

Pump connecting port

(PS1/4)

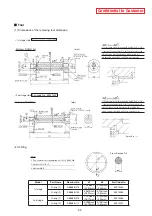

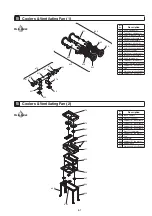

4.21.3 Shrink-Fitting the Pinion Gear

Shrink-fit the pinion gear. Be sure to fully insert the

component until it comes in contact with the stepped

section of the motor. The temperature of shrink fitting

must be approximately 392

℉

(200

℃

).

Recommended equipment : SKF Oil injector 226400 series