29

①

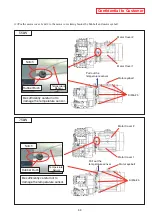

Checking the operating temperature

If the LCD monitor indicates main motor overload

[OVERLOAD: MAIN] (fixed speed type) or temperature

increase of main motor fin [FIN-T] (Vtype), investigate

the cause of the excessive heat and utilizing the

Motor

Diagnostics and Troubleshooting

chart below.

②

Cleaning

Clean the motor periodically to prevent dust

particles from accumulating inside and outside of

the motor.

When servicing the air compressor,

measure the insulation resistance of the motor

coil with a 500V megohmmeter and verify that

the insulation resistance is 1M

Ω

or more.

③

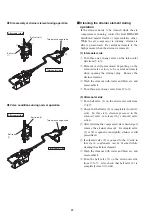

Disassembling

In a severe environment (dirty, corrosive, high dust

or high powder), disassemble and service the motor

every two years. In a normal environment, disassemble

and service the motor every six years. For the most

common motor problems, see the

Motor Diagnostic

and Troubleshooting

chart below. If the problem

cannot be solved with the chart, contact the local

HITACHI distributor/master dealer or representative

office.

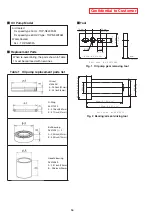

Motor Diagnosis and Troubleshooting

4.11 Maintenance of Main Motor

Phenomenon

Cause

Excessive Sound

Excessive Rotation

Excessive V

ibration

Heated

Overload Indication

Breaker T

ripped

Electric Leak

Low Insulation Resistance

Corrective Action

Frame

Bearing

Installation

Loose bolts

○

◎

○

Retighten the bolts.

W

iring

Poor grounding

◎

Ground properly.

Inadequate breaker capacity

Note 3

○

◎

Replace with properly specifi ed capacity breaker.

Broken wires

○

Install new wires.

Failed breaker, controller or contactor

○

Note 3

○

Check the contacts and replace if necessary.

Environment

Dust accumulation reduced cooling

performance

○

Properly clean motor.

Excessive ambient operating

temperature

◎ ○ ◎

Improve the room ventilation or contact the local

Hitachi distributor.

High humidity

◎

Contact the local Hitachi distributor.

Large external vibration/shock

◎

Take vibration and shock measurements.

Power Supply

Phase-lacking operation

◎ ◎ ○ ◎

◎ ○

Check the brealer, contactor and motor wirings.

Widely dropped voltage

○ ○

◎

◎

Check the wire thickness and length and contact the

local power utilities company.

Fluctuating voltage

○

○ ○

○

Contact the local power utilities company.

Load

Overload

○

◎

◎ ○

Check the capacity control system.

Thrust force by the machine

○

○

◎

Check the contact condition of bull gear and pinion gear.

Excessive bearing noise NOTE 2

◎

◎

◎ ○

Contact the local Hitachi distributor.

Burnt motor coil NOTE 2

○ ○

○

◎ ◎ ◎ ○

Contact the local Hitachi distributor.

NOTES)

1.

◎

: Close relationship between the cause and type of problem.

〇

: Relationship between the cause and type of problem.

2. Detect the fundamental cause of the problem and take corrective action.

3. Breaker, controller or contactors are hot.