6 - Maintenance

81

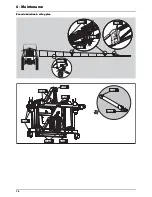

100 Hours Service - Check/Adjust Drawbar (Fixed High Drawbar only)

If too many movements occur sideways, the drawbar must be adjusted.

1.

Loosen counternuts (B).

2.

Regulate on the turnbuckles (A) on each side to adjust and center

the drawbar.

3.

Tighten counternuts (B).

250 Hours Service - Readjustment of the Boom

See section “Occasional Maintenance” on page 85.

250 Hours Service - Hydraulic Circuit

Check the hydraulic circuit for leaks and repair, if needed.

Refill nitrogen accumulators for:

•

ParaLift

•

Suspension (if fitted)

±

WARNING! Hoses for boom lifting device must be changed after every 5 years of use.

±

WARNING! Nitrogen accumulators may contain oil under pressure.

250 Hours Service - Hoses and Tubes

Check all hoses and tubes for possible damage and proper attachment. Replace damaged hoses or tubes.

250 Hours Service - Wheel Bearings

Check for play in the wheel bearings:

1.

Place stop wedges in front of and behind the left wheel and jack

up right wheel.

2.

Rock the right wheel to discover possible play in the bearings.

3.

If any play, support the wheel axle to prevent the trailer from falling

down from the jack.

4.

Remove hub cap (A) and cotter pin (B). Turn the wheel and tighten

the castle nut (C), until a slight resistance is felt in the wheel

rotation.

5.

Loosen the castellated nut until the first notch - horizontal or

vertical - is aligned with the cotter pin hole in the shaft.

6.

Fit a new cotter pin and bend it to keep it in place.

7.

Fit the hub cap to the hub again.

8.

Repeat the procedure for the left wheel.

Summary of Contents for NAVIGATOR FORCE

Page 4: ...1 EU Declaration 4 ...

Page 12: ...2 Safety Notes 12 ...

Page 54: ...4 Sprayer setup 54 ...

Page 76: ...6 Maintenance 76 Boom lubrication oiling plan ...

Page 112: ...8 Technical specifications 112 ...

Page 116: ...Index 116 ...

Page 118: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...