Note

: The diagram wiring of the fan motor maybe have some difference from the real parts due to

different types of fan motor ,the detailed information can refer to the fan motor nameplate.

47

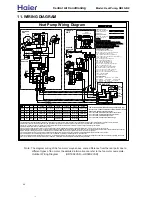

11. WIRING DIAGRAM

40

BK

OPTIONAL

TL

RD

TL

BK

RD

RD

RD

L1

BRK

INDOOR

UNIT

BK

RD

L2

BK

ELECTRIC HEATER KIT

FL

RD

FL

OFM

6

BR

BR

R

M

S

5

RCAP

C

H

C

RD

S

YL

STRLY

H

Heat Pump Wiring Diagram

LINE VOLTAGE

FACTORY STANDARD

FIELD INSTALLED

OPTIONAL

LOW VOLTAGE

FACTORY STANDARD

FIELD INSTALLED

OPTIONAL

SW

-1

HA

TS

CA

FA

N

ON

RH

S

-1

AUTO

HEAT

OFF

OFF

COOL

HEAT

RHS-2

LED

COOL

OD

A

SW

-2

5 6

WH

PU

BL

4

3

BR

6

6

WH

3

3

5

5

4

4

2

2

1

1

PU BL

BK RD

BR

9

1

BK

208/230V

BK

L1

60Hz 1PH

BCR

GND

IBM

WH

L2

2

BL

S

R

PU

BR

BCAP

230

TRAN

208

BK

BK

L1

BK-HI

3

RD

BR

M

STCAP

RD

CC

RD

PU

4

RD

RD

YL

LPS

PIPE SENSER

VS

PS

VS

CN7

VENT SENSER

PU

F

CN5

YL/GR

HR60D1VAR

HR48D1VAR

HR42D1VAR

HR18D1VAR

HR24D1VAR

HR30D1VAR

HR36D1VAR

RD

C1

C2

C3

P3

P2

P1

GR

OUTDOOR TEMPERATURE

XT

PS

CT

1

JK3

LED

CN8

A

ODS

V

CN4

V

CN3

F

JK4

CN6

PU

RD

RD-LO

GR

BL

W

Y

O

W2

C

G

HEAT CONTROL

RESISTANCE

WH

BR

BL

L2

OR

RD

R

8

7

T

G

C

R

INDOOR FAN CONTROL

HR18E1VAR

14SEER

loop CT twice

HR42E1VAR

loop CT once

W

YL

HPS

COMPRESSOR

REVERSING VALUE

A

JK2

GY

YL OR WH

V

C

F/H

S

CN1

C

RD

RD

CN2

RD

N

L

JK1

BL

T

O

Y

W

C

R

8

7

13SEER

13SEER

HR18D2VAR

loop CT twice

13SEER

loop CT twice

OFF

OFF

Dip 3

Dip 4

loop CT once

24VAC POWER

24VAC COMMON

HR42D2VAR

loop CT once

13SEER

C

2

RD

COM

LED Flash Codes(LED illuminates during unit operation only )

COMPONENT CODES

BCR - BLOWER CONTROL RELAY

BCAP - RUN CAPACITOR BLOWER MOTOR

CC - COMPRESSOR CONTACTOR

CCH - CRANKCASE HEATER (OPTIONAL)

CHS - CRANKCASE HEATER SWITCH (OPTIONAL)

CMPR - COMPRESSOR

DFC - DEFROST CONTROL BOARD

HPS - HIGH PRESSURE SWITCH

LPS - LOW PRESSURE SWITCH

IBM - INDOOR BLOWER MOTOR

ODS - OUTDOOR TEMPERATURE SENSOR

OFM - OUTDOOR FAN MOTOR

RCAP - RUN CAPACITOR COMPRESSOR

RVS - REVERSING VALVE SOLENOID

STCAP - START CAPACITOR (OPTIONAL)

STRLY - START RELAY (OPTIONAL)

STRTH - START THERMISTOR (OPTIONAL)

TRAN - TRANSFORMER

230/208 SELECTABLE

COLOR CODES

BK - BLACK BL - BLUE GY - GRAY

BR - BROWN GR- GREEN OR - ORANGE

PU - PURPLE RD - RED VI - VIOLET

WH - WHITE YL - YELLOW

THERMOSTAT

BK

PU

RD

USE COPPER CONDUCTORS ONLY

WARNING CABINET MUST BE PERMANENTLY GROUNDED

AND ALL WIRING TO CONFORM TO I.E.C.,N.E.C.,C.E.C.,

C.L.C. AND LOCAL CODES AS APPLICABLE.

REPLACEMENT WIRE MUST BE THE SAME GAGE AND

INSULATION TYPE AS ORIGINAL WIRE.

CMPR

UNIT

OUTDOOR

6

C

BK

CCH

L1

GND

L2

208/230V

RVS

60Hz 1PH

1

OFF

OFF

Dip 1

Dip 2

R

WH

BK

M

HR36E1VAR

HR30E1VAR

HR60E1VAR

HR36D2VAR

HR30D2VAR

OFF

ON

ON

ON

HR60D2VAR

OFF

OFF

OFF

OFF

1)Confirm defrost control board (DFC) dip switch settings and CT application for system selection as shown in adjacent table. Optional components may be field or factory installed.

2)If LPS and/or HPS not installed or removed, a jumper wire must be present across connector CN8 of the defrost control board (DFC) for system to operate.

3)For proper system operation, consult indoor unit and outdoor unit installation instructions to confirm system match up and blower speed selection.

4)Alternate double pole contactor used on some systems.

5)Only one start assist method to be used at a time, consult outdoor unit installation instructions for application information. Use only factory approved accessories.

6)Optional OFM components may connect capacitor common and motor common, for reciprocating compressor there may have crankcase heater consult outdoor unit installation instructions for

details. Select the running capacitor(one or dual)and connect. If IFM or OFM only have one capacitor wire, connect Com wire to capacitor.

7)To protect equipment from operation at low outside ambient temperatures,connect outdoor unit terminal T and equipped indoor thermostat terminal T as shown.

8)To activate electric heat circuit during defrost cycle, connect outdoor W terminal to available indoor heat circuit W or W2 .

power connections directly to electric heater kit power terminals. Consult heater kit installation instructions for complete details.

HR48E1VAR

OFF

OFF

OFF

ON

HR48D2VAR

HR24D2VAR

HR24E1VAR

continuous on - 24VAC supplied to Y terminal of defrost control.

Flash on/off - System in defrost operation.

Outdoor Wiring Diagram (HR18D2VAR—HR36D2VAR)

Central Air Conditi

oning

Model: Heat Pump,

HR13-D2

1/2 + 1/2 1 flash - Pipe/coil sensor open or short circuit.

1/2 + 1/2 4 flash - CT sensor out of max range.

1/2 + 1/2 2 flash - Vent/suction sensor short circuit.

14SEER

1/2 + 1/2 3 flash - LPS & HPS open circuit.

9)Indoor unit shipped without optional electric heater kit. To install optional heater kit, remove power pig tail up to 9 pin plug. Install heater kit and connect with mating 9 pin plug. Run system