4

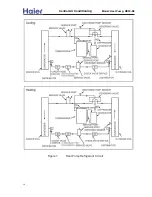

Fig.1-1

Fig.1-2

safe access to measure u

nit

nit

pressures .

Fig.1-3

valve in the cooling mode.

Fig.1-4

ACCESSORIES:

CABINETS

:

Constructed of powder painted galvanized steel to provide a durable finish

and protection for the outdoor coil.

FAN GUARD AND MOTOR BRACKET:

BASE PAN

: This deep-drawn base keeps the bottom of the coil off the

ground, has weep holes to allow for complete drainage.

LOW AMBIENT CONTROL:

This factory installed option allows for low temperature operation in

the cooling cycle ambient temperatures down to 0

℉

. This control should be installed in units that

operate in cooling when outdoor ambient temperatures below 65

℉

, and is recommended for all

commercial applications.

and system pressure combinations. This option maybe required on reciprocating compressors with

START COMPONENTS :

This option provides additional starting for covering a wide range of voltages

SERVICE VALVES AND PRESSURE PORTS:

Mounted external to the cabinet for easy access at

installation and during service.

Welded powder coated guard with independent rod and band motor

SERVICE VALVES

:

Facilitates unit servicing and provides a reliable an

d

bracket, unit top has a deep draw fan venturi for efficient air flow.

flowcheck piston metering.

FLOWCHECK DISTRIBUTORS

: Outdoor units use the Flowcheck Distributor to act as an open check

Central Air Conditi

oning

Model: Heat Pump,

HR13-D2