27

6

Maintenance

The following control and maintenance work has to be carried out:

Work

When

you start

working

When

necessary

Comments

General visual inspection:

– Housing

– Anchor bolt

X

X

Check screws

X

After first operation or inspection

Cleaning

X

If the machine is very dirty, it may be

necessary to use a high-pressure

cleaning device.

If necessary, dismantle the housing

and remove dirt/foreign bodies.

Lubrication

X

Fill in motor oil drop by drop.

After a high-pressure cleaning device

was used:

Soak the machine in motor oil and let

the oil run off.

Rope: Visual inspection

– Pressing clamp

– Tow hook and safety device

X

X

Check if there is any deformation,

damage or tears.

Rope: Check diameter

X

Replace a rope when it is worn, for

values see Chapter 3

The machine, rope and accessories have to be checked at least

every 12

months by a certified body.

(see label on hoist). During this inspection, all

parts must be checked for deformation, wear and tear. The test results have to

be entered in a test book or on page 4 in this booklet.

The user is responsible for seeing to it that these inspections are carried out.

Furthermore, additional inspections should be carried out by an expert in

accordance with the local regulations or when the machine was used under

difficult operating conditions.

All repair work has to be carried out by a certified body only.

7

Disposal

Please observe the regulations regarding disposal that are effective in the respective country.

When dismantling the machine, separate defective parts according to type of material for recycling

purposes.

Keep metal and plastic parts separate from one another or take them in for recycling.

Please bear in mind that protecting the environment and recycling materials benefits all of us.

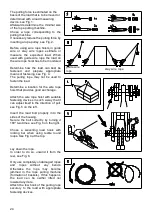

Lists of spare parts

The lists of spare parts for the 5 rope pulling machines are provided on the last pages of the operating

manual.