21

2.3.3 Pulling rope

The quality of the rope is important with respect to the reliability of the drive system. The structure of

the rope and its inherent stability have to endure the loads that will occur.

Therefore only use ropes delivered or approved by HABEGGER, i.e. 4 x 19

(only

HIT 6

) or 6 x 19 (

HIT 10, HIT 10 special, 16, 32

) with polypropylene

core. Do not grease the pulling rope.

We refuse to recognize any damages and claims for liability that can be traced back to the use of

unsuitable ropes or ropes not approved by us.

The diameter of the rope must correspond to the information provided on the typeplate.

Danger of injury! Wear gloves when handling wire rope hoists and wire ropes.

It is prohibited to carry out any welding work on the tow hook or the rope. When carrying out electric

welding work at another place, make sure that the welding current is definitely not conducted through

the pulling rope or the machine.

Danger! The heat can reduce the strength of the hook or rope. Danger of

breaking!

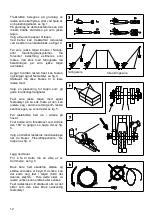

Damage to the rope: Do not use pinched, twisted, flattened or kinked ropes,

ropes with twisted or broken strands.

Ropes with protruding wires: Remove protruding wires.

Damage at the beginning or end of the rope: If possible, shorten the rope.

Replace or repair the hook if the safety catch is missing.

Replace the rope when it is worn by more than 10% of the nominal diameter at

its thinnest point.

Do not let rope joinings, sleeves, pressure heads, short splices, etc., run against the wire rope hoist.

When the rope has to be guided over sharp edges, obstacles, etc., protect the rope by means of

adequate ground rollers or pads of wood or plastic.

The rope has to be laid out in an expert manner, i.e. it has to be unwound from the reel in such a way

that no loops are formed, no strands are broken, and the rope is not twisted.

Danger! Before the end of the rope reaches the machine (at least 0.5 m should

still be available): Stop unwinding the rope. Danger of crashing!

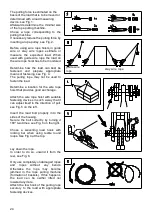

2.3.4 Load

The load has to be fastened to the towhook by means of appropriate fastening devices such as hooks,

slings, straps, belts, shackles.

Always attach loads at the centre of the hook. The tip of the hook may not bear any load.

Make sure there are no obstacles that could cause the load to tip or get stuck.

Avoid any uncontrolled loading (e.g. buckets, containers) during lifting or in intermediate positions, or

control the loading with a load measuring device.

While bracing or anchoring the machine, take into account the possible tension peaks (in a static

condition) caused by external influences. (wind, snow, ice)

Do not let the load fall into a slack rope.