20

2.3

General safety instructions

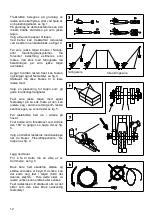

2.3.1 Location

Make sure that the machine is always operated on a firm and safe location.

Always stand outside the danger zone of the load being moved; never stand in the "tangle" of the rope

where it exits the machine.

You need freedom of movement. Thus, make sure you have a sufficiently large supporting surface.

Never use ladders as the supporting surface.

If the location is not suitable insert the guide pulley and choose a better location.

Hazard of contact near overhead lines or high-voltage lines!

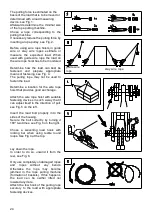

2.3.2 Anchorage

The anchoring point must be able to endure the pulling force that can be expected (if necessary, check

in advance).

The best anchoring points

are:

•

firm objects and constructions,

•

rings set in concrete,

•

hooks or poles.

Natural anchoring points:

•

strong/heavy blocks of rock,

•

trees,

•

other suitable objects.

Technical anchorages:

•

anchorage rail Habegger with poles,

•

rock anchor, concrete anchor

•

round wood anchor in ground where holes can be dug.

These types of anchors depend on the quality of the ground.

Use sufficiently strong straps or loops to fasten the machine to the anchor bolt.

Always fasten the rope pulling machine at the anchoring bolt.

Never stand the rope pulling machine on the rope lead-in or the housing.

The machine has to be able to adjust itself freely in the direction of pull of the rope.

Otherwise there is the danger of breaking the housing in both cases!

If the anchor bolt is attached directly to a fixed pulling lug (e.g. an eye made of flat material or hook), it

must be ensured that the bolt definitely cannot become jammed. Danger of the housing breaking!

Equally, the housing of the rope pulling machine must never come into contact with an obstacle.

Danger of the housing breaking!

Do not use damaged rope straps or fastening slings.

The clutches of the rope and safety devices must not loosen when the rope is not taut.

When the machine is used at the same location for a long period of time: check the

anchoring points regularly!