Operating Manual

Initial Machine Set-up

12/19/02

19

IMPORTANT: DO NOT overfill the reservoir. The Level Indicator should read

approximately 1/2 full with liquid.

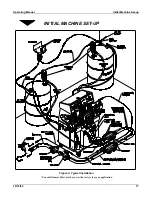

5. The hydraulic pumps need to be full

with hydraulic fluid. Remove each

case drain hose from the reservoir.

Gradually add fluid until the pump

and hose is full and air bubbles stop.

6. Locate the Pump Lube Reservoir

included with the Accessory Package.

Prepare the Lube System for use as

follows:

Figure 7. Hydraulic Fluid Level

NOTE:

Use only Gusmer Pump Lube

(P/N 0960-1-GAL)

NOTE:

The tube that supplies Pump Lube

to the Lube Cup must be at the

upper level of the reservoir and

the return tube is at the lower level

of the reservoir. This will ensure

that any Isocyanate Crystals will

settle to the bottom of the

reservoir and not return to the

Lube Cup

a) Fill the Lube Reservoir.

b) Thread the reservoir onto the

Reservoir Cap Assembly and

place it into the bracket.

c) Push the Supply Tube

approximately 1/3 of the

way down into the Lube

Reservoir.

d) Push the Return Tube down

into the Lube Reservoir until

it reaches the bottom.

e) Place the Lube Reservoir

into the Bracket. The Lube

System is now ready for

operation. No priming of

the system is required.

Figure 8. Lube Reservoir Installation

7. Connect the Isolation Hoses to their

respective Primary Heater outlet

fittings.

IMPORTANT: To prevent the

inadvertent connection of a hose to

the wrong chemical source, the

Isocyanate hoses are color-coded red

and the Polyol hoses are color-coded

blue for easy identification. In

addition, the Polyol and Isocyanate

hose fittings have different thread

sizes, making it virtually impossible to

improperly connect the hoses.

Figure 9. Isolation Hose Connections