Operating Manual

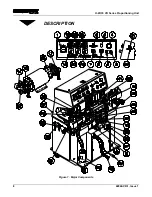

Description

12/19/02

9

1. MAIN POWER DISCONNECT- Controls power to all circuits. Must be ON for

any function of the proportioning unit to operate. The disconnect can be locked in

the OFF position for OSHA required lockout/tagout during machine maintenance.

2. MAIN POWER LIGHT (WHITE)- Lights up when the Main Disconnect Switch is

in the ON position and the control power transformer is operational.

3. CONTROL POWER SWITCH- Turns the unit’s 120VAC control power circuit on

and off. In the ON position, the amber light within the switch lights up. Removal of

control power stops all machine operation including motion and heating.

4. EMERGENCY STOP SWITCH- Interrupts the units control power circuit to stop

all motion and heating. Switch mechanically locks in the stop position. Turn the

switch clockwise to reset it and restore normal operation.

5. HYDRAULIC MOTOR SWITCH- Controls power to motor circuit. In the ON

position, the green light within the switch lights up.

6. POLYOL COUNTER- Records the cycle count of the Polyol proportioning pump.

One cycle equals two strokes (one in each direction); used to determine ratio.

7. ISOCYANATE COUNTER- Records the cycle count of the Isocyanate

proportioning pump. One cycle equals two strokes (one in each direction); used to

determine ratio.

8. PUMP MODE SWITCH- Controls operation of the proportioning pump Hydraulic

Drive System

•

RUN- Should be in this position for the pump system to operate properly.

This position is used for all normal operation of the pump system, while

dispensing chemical. Hydraulic system will be energized when a special

dispensing gun is triggered.

•

RETRACT- The pump system is energized so that the Isocyanate pump

shaft is retracted into the pump cylinder. This shields the Isocyanate pump

shaft from air to limit crystallization during periods of machine inactivity.

The retract position should be used during any period of machine inactivity

•

SERVICE – With the recirculating ball valves open, the pump system is

energized and ratio can be determined with the counters or material can be

conditioned. With the recirculating ball valves closed, the system will build

pressure.

9. ISOCYANATE RECIRCULATING BALL VALVE – Ball valve on the Iso

material that either allows the system to recirculate chemical back to the chemical

drums during Service Pump Mode or prevents chemical from returning to the

chemical drums during Run Pump Mode.

10. POLYOL RECIRCULATING BALL VALVE – Ball valve on the Polyol material

that either allows the system to recirculate chemical back to the chemical drums

during Service Pump Mode or prevents chemical from returning to the chemical

drums during Run Pump Mode.