H-20/35 VR Series Proportioning Unit

22

42942-VR-1, Issue 1

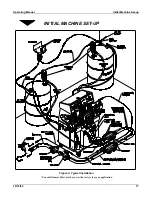

11. Properly ground all auxiliary equipment. The high velocity flow of fluid can create

static sparking, which may cause fire or explosion. Certain solvents that are

commonly in use with this equipment are flammable and may present a flash danger

to the operator. Proceed as follows:

a) Ground the material supply. (Transfer Pumps/Day Tanks)

b) The 2:1 Transfer Pump has a ground lug. Ground the pump in accordance

with the instructions provided with the pump.

c) Check that the Proportioning Unit ground at the main electrical source is

installed in accordance with the National Electrical Code. If a generator

will be powering the unit, consult with your electrician about additional

grounding measures that may be required.

d) Connect the material supply system to the inlet of the proportioning unit.

Use caution when connecting the chemical hoses to the appropriate

Proportioning Pump.

IMPORTANT: Before using the equipment, it is necessary to purge the entire

chemical system of air and mineral oil (left over from factory testing) and to verify

proper rotation of the motor.

13. To purge the machine and verify proper rotation proceed as follows:

a) Turn on the Main Air Supply to the Transfer Pumps and drums/day tanks.

b) Open both Iso and Polyol Inlet Supply Valves. It is a good practice at this

point to check for chemical leaks.

NOTE:

If the inlet chemical pressure is

below 40 psi, the audible alarm

will sound when the Control

Power Switch is turned ON.

c) Turn the Hydraulic Pump Flow Adjustment clockwise for both pumps until

approximately ¼” of the adjustment is showing.

d) Turn ON the red Main Disconnect. The white Main Power Light will light

up.

e) Turn ON the amber Control Power Switch. The light within the switch and

the Temperature Controllers will light up. If the audible alarm sounds, reset

by pressing Alarm Rest on side of console.

f) Take the Coupling Block and hold it with the Iso and Polyol Ports over

separate containers, open both manual valves.

g) Turn ON the Hydraulic Motor Switch.

h) Turn the Pump Mode to the SERVICE Position.

WARNING:

A QUALIFIED ELECTRICIAN SHOULD PERFORM THIS STEP.

If the pumps don’t cycle back and forth, the motor has been wired incorrectly. Turn OFF

Hydraulic Motor, Control Power Switch and Main Disconnect. Close inlet supply valves.

Remove power from power cord and switch any two leads to the Main Disconnect. Return

to step d)

i)

Allow material to flow out of the coupling block until all spitting of air stops

and all traces of residual material have disappeared.

NOTE:

Disposal of waste chemicals must

be in accordance with local, state,

and federal codes.

j)

Turn the Pump Mode to the RUN Position and close inlet supply valves.

k) Allow the Hydraulic Pumps to run for 10 –15 minutes to remove all residual

air in the hydraulic lines.